Categories

Close

-

Linear Motion Products

Back to main categories-

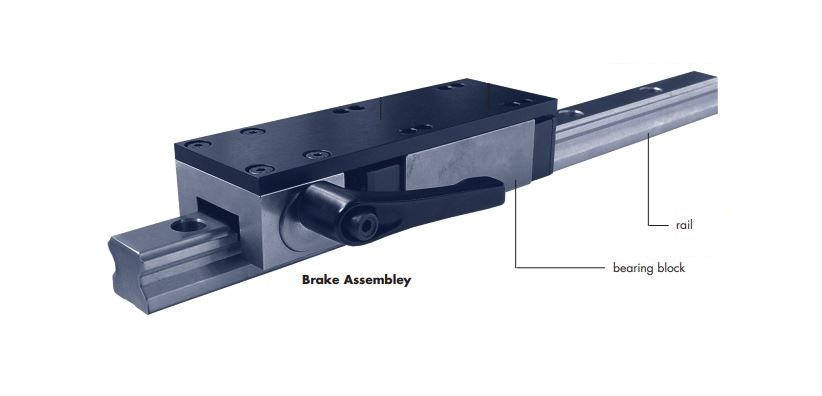

Linear guide rails

Back to subcategories

-

Ball spindles

Back to subcategories

- Linear bushing and shafts

- Trapezoidal screws

-

Linear Modules

Back to subcategories

-

Actuators

Back to subcategories

- Lubricants for linear motion systems

- Energy or cable chains

- Drawer slides

- Ring guides, track systems and segments

Linear Motion Products in Online Shop at incredible prices. You can choose between profiled linear guides systems (linear rails, blocks and linear ball bearings), round shaft linear slide system with linear ball bushings, ball screws, ball nuts and trapezoidal screws. From our wide offer you can find perfect linear motion products for your CNC machine, 3D printer or other application. All bearing rails and shafts can be cut to desired length. We ship worldwide. -

Linear guide rails

-

Alu profile systems

Back to main categories- Aluminium Profiles

-

Joining Elements

Back to subcategories

-

Accessories

Back to subcategories

- Roller rails

- Tubular modular systems

A comprehensive system of profiles complete with an enhanced range of fixing elements including brackets, flexi connectors and accessories, to enable complete frames to be constructed by the customer from the components, or supplied flat packed for simple re-assembly. In addition, we will ship completed frames to your requirements designed on our in-house 3D drawing package. Reduced material costs, improved flexibility and assembly time savings are available by using aluminium profiles over steel for constructing machine frames, and machine fencing requirements can be fulfilled using elements from our Machine Fencing System. Wide range of profile sections with Tee slots or plain sides. Custom designed 3D frame design and build service. Supplied in component form, flat packed for re-assembly or completed frame. Profiles allow the fixing of linear systems. Fencing system available for machine protection. Range is constantly being widened with new components added regularly. -

Bearings

Back to main categories- Radial ball bearings

- Radial roller bearings

- Grease for bearings

- Thrust bearings

- Thrust roller bearings

- Combined axial radial bearings

- Cam followers

- Spherical plain bearings

- Rod ends

- Plain bearings

- Washers & strips

- Take-up housing units

- Bearings with housing

- Bearing housings

- Bearings accessories

- Linear bearings for round shafts

- Bearings sleeves

- Bearing washers

- V-rings

- Housing seals and covers

- Oil seals

-

Ball Transfer Units

Back to subcategories

- Standard Ball Transfer Units

- Flange Fixing Ball Transfer Units

- Thread Fixing Ball Transfer Units

- Base Fixing Ball Transfer Units

- Mini Ball Transfer Units

- Float-On Ball Transfer Units for Glass Handling

- Hevi-Load 0,1,2,3 Ball Transfer Units

- Spring Loaded Ball Transfer Units

- Fixing Clips for Ball Transfer Units

- Other Ball Transfer Units

-

Power transmission systems

Back to main categories