The 6 steps of ball screw selection

When choosing a suitable ball screw and nut you need to pay attention to several factors. The most important factors are presented below.

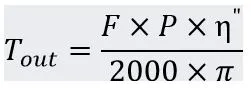

1. Rotational speed

n= rotational speed [rpm]

v= linear velocity [m/min]

p= lead [mm]

Rotational speed should not exceed 3000rpm.

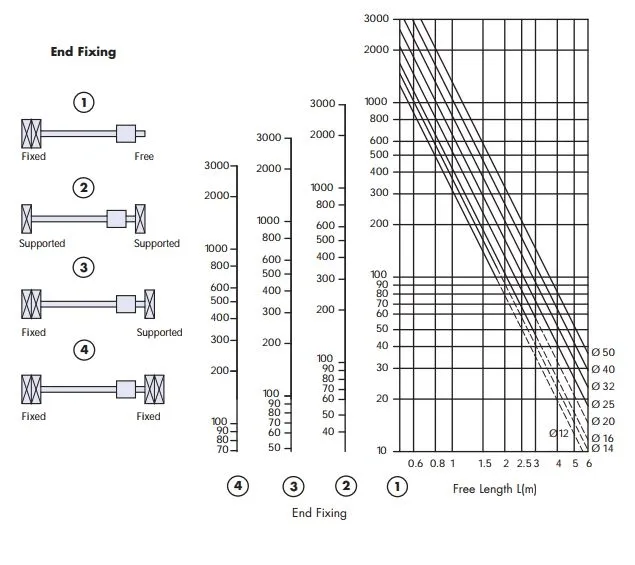

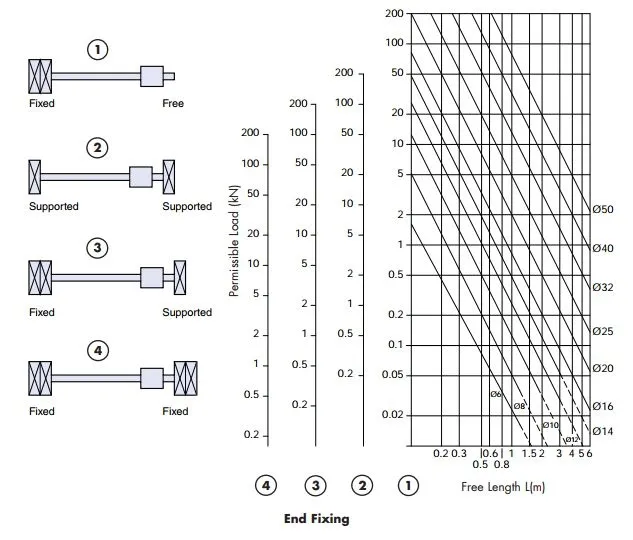

2. Critical speed

The permitted maximum speed of all ball screws depends on the screw diameter, end fixing type, and free screw length. This value can be read from the graph below. The graph shows 4 speeds matching the 4 mounting options and incorporates a safety factor of 25%.

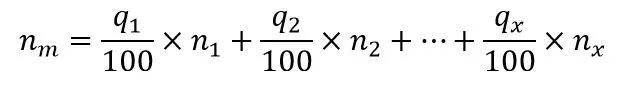

3. Buckling load

The maximum axial load which can be carried depends on the diameter of the ball screw, end fixing, and free length. The buckling load for 4 different end fixings is shown below; the chart includes a safety factor of 100%.

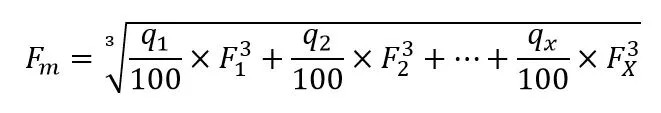

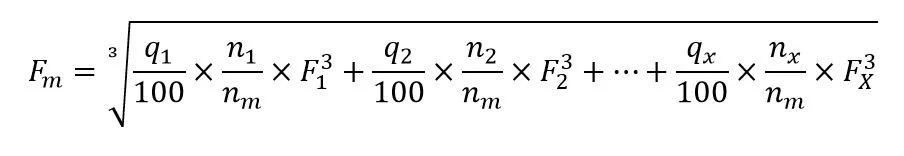

4. Average speed and average load

nm= average speed [rpm]

q= time fraction [%]

Fm= average load

Where the speed varies through the machine cycle, the average speed is calculated as follows:

Where the load varies, the average load is calculated as follows:

Where the load and speed vary, the average load is calculated as follows:

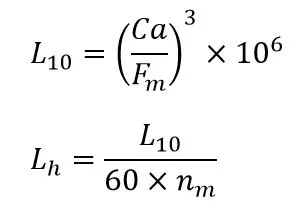

5. Service life

The basic service life is expressed by the number of revolutions that will be attained or exceeded by 90% of a representative sample of identical ball screws before the first signs of material fatigue become evident. Life in hours can be calculated by using the average speed.

L10= service life [revolutions]

Fm= average load [kN]

Ca= dynamic capacity [kN]

Lh= service life (hours)

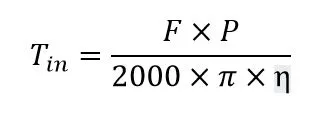

6. Torque calculation

Input torque for conversion of rotary motion to linear motion:

Tin= drive torque [Nm]

F= operating load [N]

P=lead [mm]

η= efficiency (approximately 0.9)

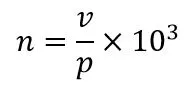

Output torque for conversion of linear motion to rotary motion:

Tout= transmitted torque

η”= efficiency (approximately 0.8)

Source: HepcoMotion, BSP ballscrew premier

Leave a Comment

Your email address will not be published. Required fields are marked *

2 Comments