Basic ball screw terminology

When selecting various components for ball screw assemblies one must understand the common terminology used to describe their function and structure. To avoid future misunderstandings upon ordering ball screw components, let us go through the following terms which are widely misused in everyday practice.

ABC of Ball Screws

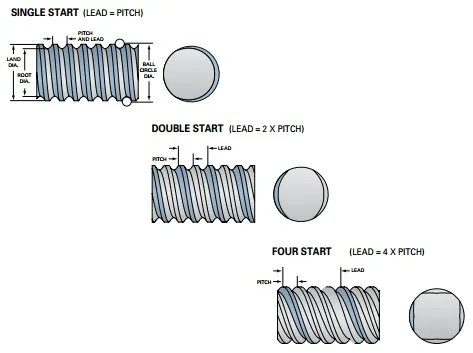

Lead: Lead is the amount of a linear advance caused by one rotation of the ball screw.

Pitch: The distance between screw threads. Lead and pitch are not equal for screws with multiple starts. For single-start screws, lead and pitch are equivalent.

Multiple start screw: A screw with more than one lead or start.

Pitch Diameter: The diameter of a theoretical cylinder passing through the centers of the ball bearings.

Root Diameter: The minor diameter of the screw shaft measured at the root of the ball grooves.

Circuit: A closed path of recirculating balls.

Deadband: The range through which a nut can be turned without engaging the balls.

Dynamic Load: The maximum load that a ball screw assembly can maintain for a prescribed length of travel.

Static Load: The maximum non-operating load capacity at which damages to the ball track or plastic deformation of the balls will not occur.

Tension Load: A load that would stretch the ball shaft.

Rigidity: A characteristic that defines resistance against deformation when an outer force acts on the ball screw.

Critical Speed: The angular velocity at which the screw or nut develops severe vibrations which can cause permanent damage to the ball screw configuration.

Although these terms are all linked to one another, each has a different meaning and importance to ball screw design and performance.

Leave a Comment

Your email address will not be published. Required fields are marked *