DIY CNC – Linear guides and ball screws from TBI Motion

When it comes to said amounts, I am very critical of the universally popular shopping in the Far East with a credit card payment. With smaller machines and investments, one can justify the risk – which is completely value-free compared to the small machines – but with four-figure amounts, I lack the necessary trust. In addition there are three-digit shipping costs from the Far East for my required sizes. I would also rather invest this money in the EU for hardware and enjoy short DPD-delivery times as well as a fixed telephone contact person in Europe. Of course, I am aware that TBI does not manufacture in Europe.

So I was looking for a distributor for TBI Motion linear motion products in Europe and found what I was looking for at TULI in Slovenia. I did not even specifically look at Eastern Europe, but to this day I have not received any evidence of a German TBI Motion dealer. Mr. Pleško from TULI is a competent contact person who always answered our questions quickly in advance, he provided 3D files for the construction and ultimately granted me an enormous discount when ordering all the linear motion products "in one go". I can recommend the shop without hesitation, the "Aftersales Service" with tips and short-term feedback works extremely well, too.

In the meantime, I have decided to bid farewell to the idea of driving my long X-side with a double ball screws, but ultimately let my gut feeling prevail and the order was subsequently supplemented. Right from the start, the two ball screws 20x10 were synchronized with a toothed belt. That is a good € 400 extra, but I could save it elsewhere e.g. on tools and the power supply.

Here is an overview of the rolled TBI Motion ball screw in the C5-class*, ball nuts with flange and their floating and fixed bearing supports:

- 2010 to X (2)

- 2010 to Y (1)

- 1605 to Z (1)

*C5-class = max 1.8/100 mm pitch error on 300 mm for about an extra € 10 net price per meter, instead of C7-class = max. 5/100 mm pitch error on 300 mm.

Since nobody was able to tell me exactly how to plan the lengths of the ball screw, I took the cutting tolerance (max. 0.5-1 mm) into account and possible expansions due to temperature changes and planned a distance of 2 mm from the finishing process to the floating bearing.

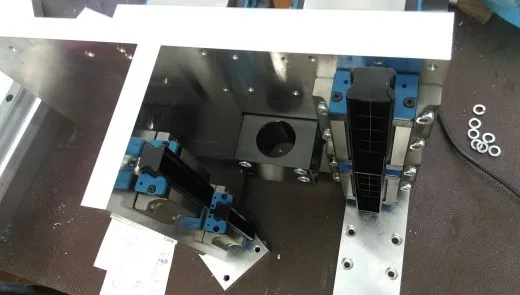

All TBI Motion linear carriages are slightly preloaded flange carriages in standard height TRH ___ FL H Z1:

- 2 x 2 x 25 to X

- 2 x 30 in front to Y

- 2 x 20 on top to Y

- 4 x 25 to Z

Z1 = slightly preloaded

The relevant linear guides come from the accuracy class H = High.

In my case, it was a two-week delivery time after a SEPA payment in advance. The goods arrived in perfect condition in three shipments via DPD after two (!) delivery days. All sensitive parts such as ball screw ends and guide cuts were extremely well secured. The ball screws were padded and secured in cut square foam blocks with notches, a very good idea.

My absolute - and complimentary - recommendation for TULI and Mr. Pleško. When ordering there, please refer to me. In the end, I will be happy to provide my shopping cart and all the lengths in the overall overview.

To sum up I can confirm that linear motion products accounts for around 50% of the material costs in mechanical construction. Since these parts play a key role in the accuracy of the machine, I only used high-quality branded products.

You can find out more information on my blog: http://selfmade-cnc.de/2017/07/27/lineartechnik-von-tbi-motion-eingetroffen/

Leave a Comment

Your email address will not be published. Required fields are marked *