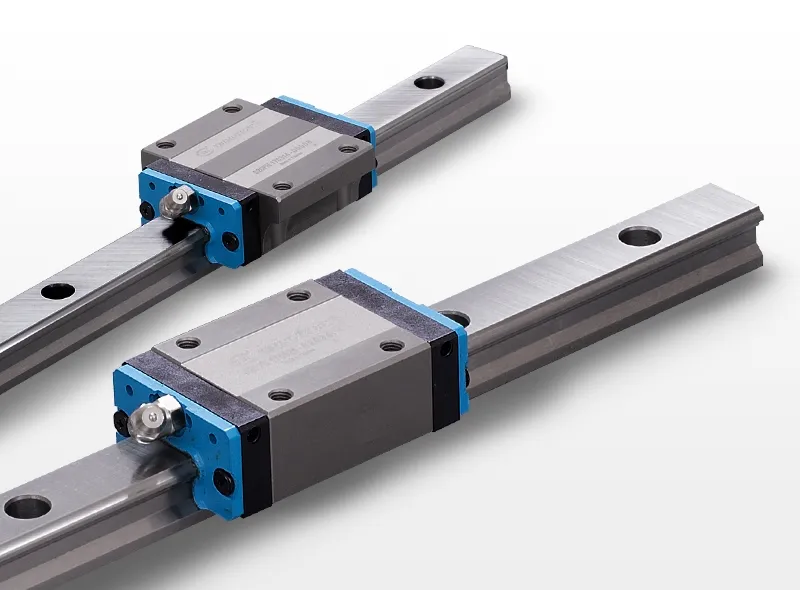

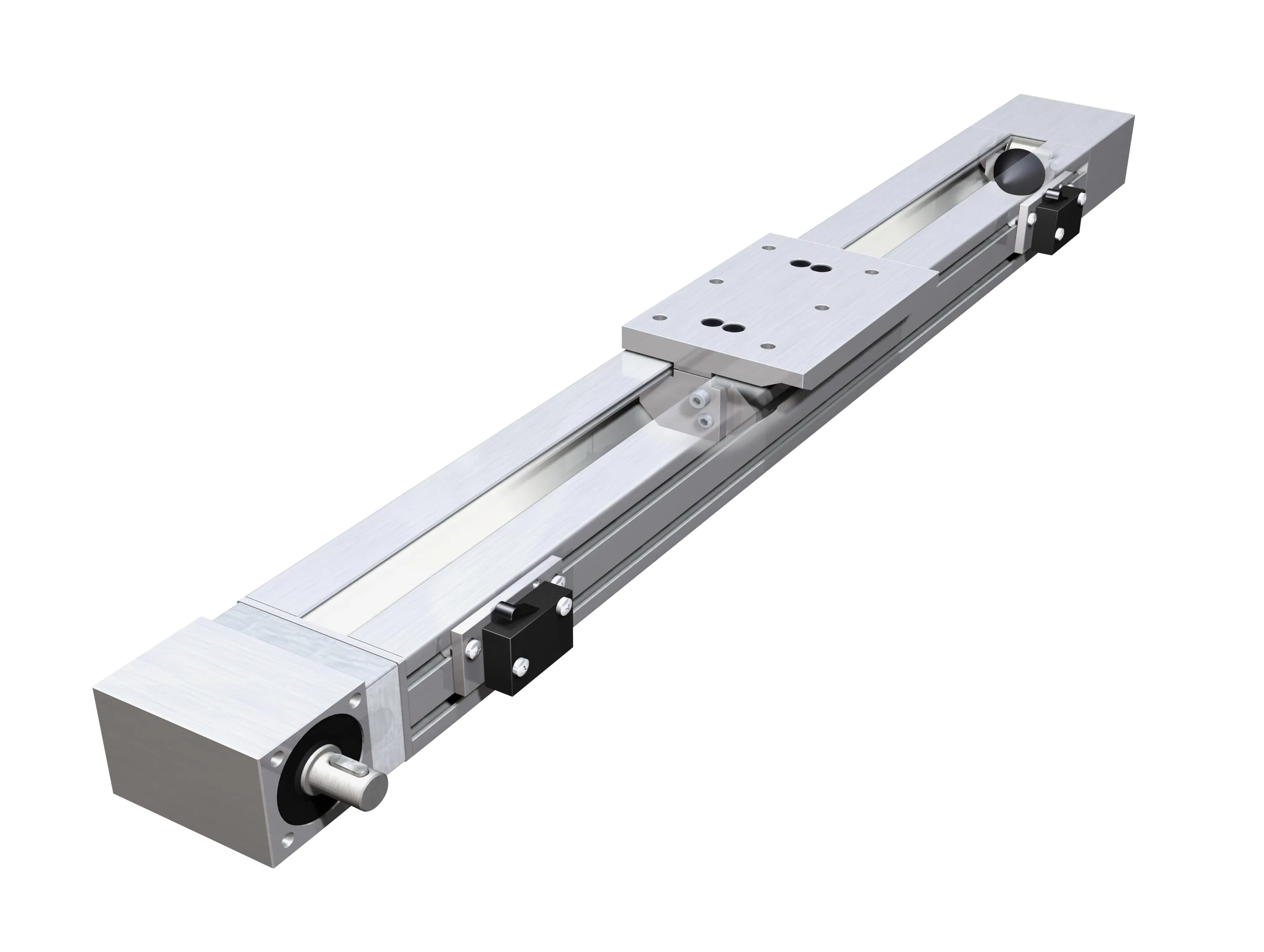

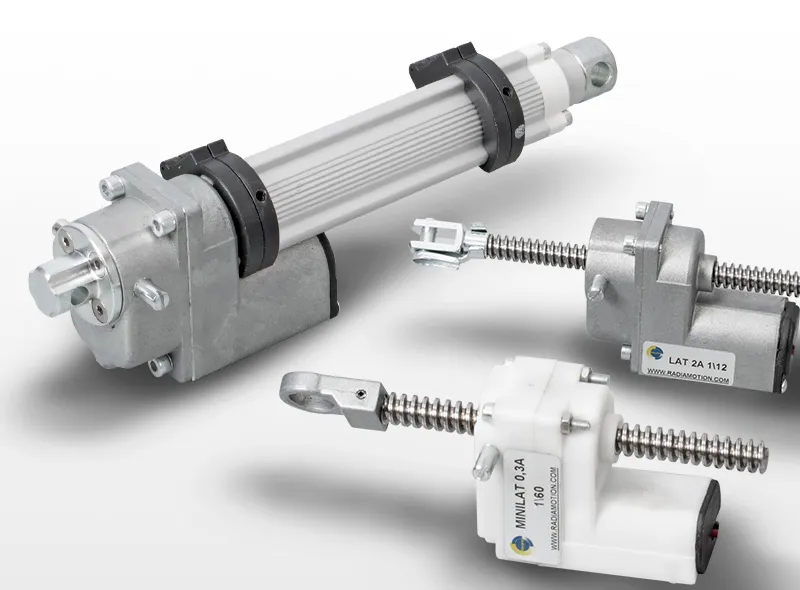

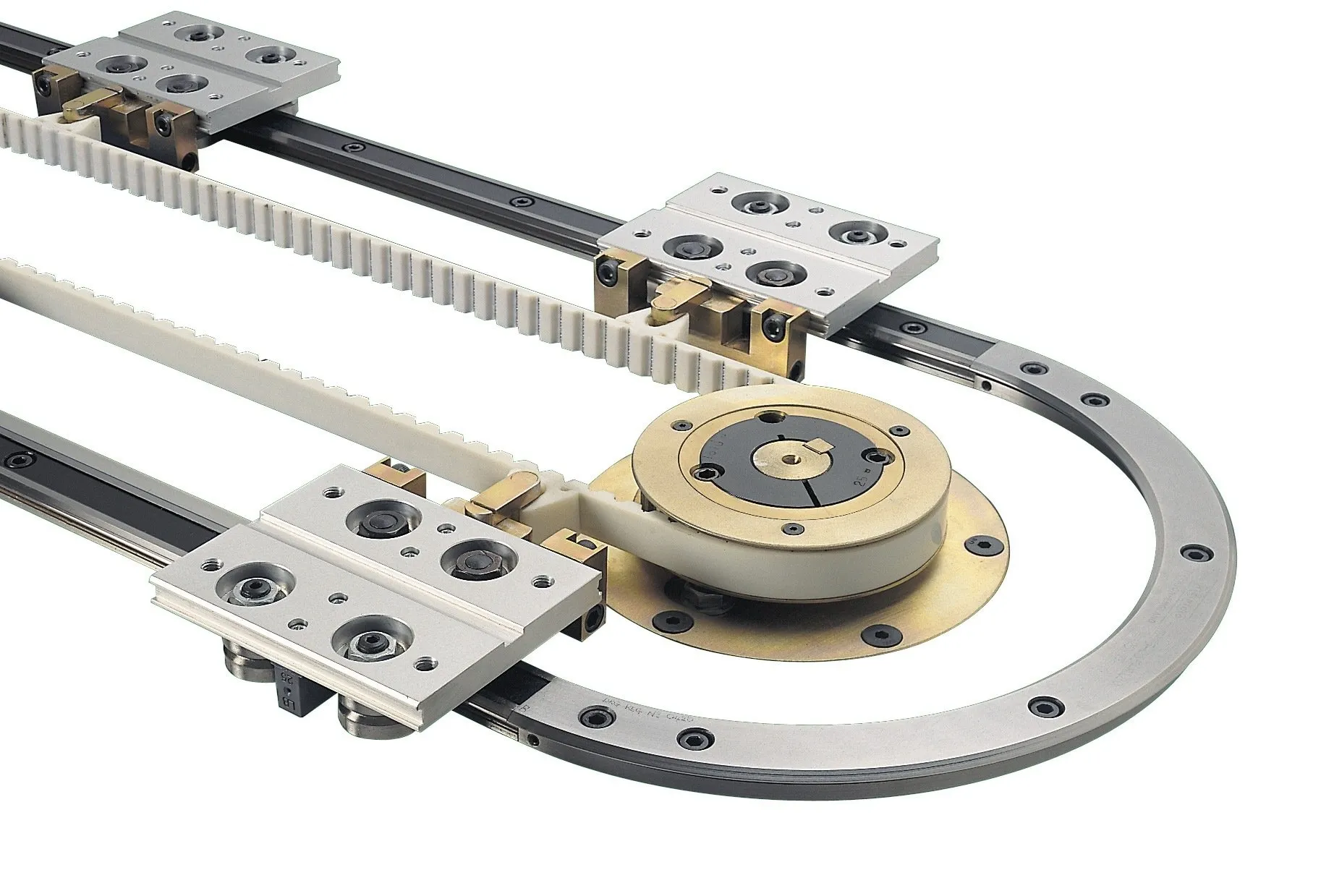

In addition to the products you can find in the online store, we also offer you a wide range of linear guides, linear blocks, ball spindles and other linear products from other premium manufacturers. With a wide network of suppliers, we offer the largest selection of linear guides and ball spindles of various manufacturers at competitive prices and with extremely fast supplies for all types of linear guides. On the following links you can also find catalogues and descriptions based on the individual linear technician: Bosch-Rexroth, INA, Schneeberger, HepcoMotion, TBI Motion, SKF, Hiwin, THK, NB, GMT, NSK and Igus.

Knowledge Base

-

Read more

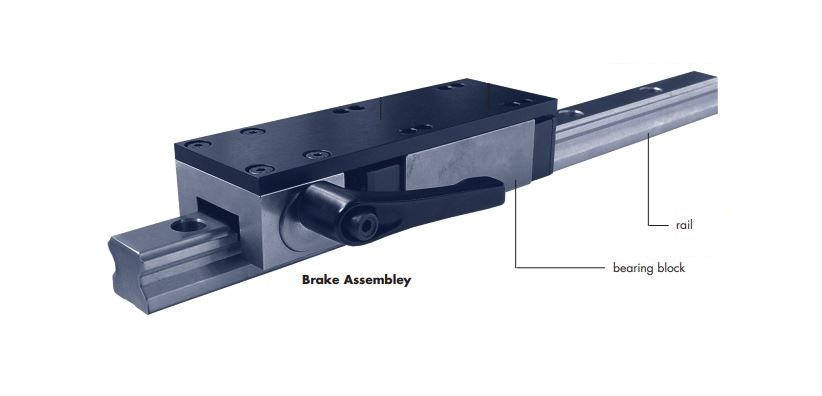

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...

-

Read more

The process of how to grease linear guide rails is the following. Start by cleaning the rails thoroughly, then choose the right lubricant and determin...