Linear actuators

Automationware heavy duty linear actuators (Stroke up to 1500 mm, Load up to 752 kN)

Electro-mechanical linear actuators enable precise, controlled, and repeatable movement in linear drive applications like pushing/pulling, opening/closing, clamping/gripping, tilting and raising/lowering. Linear actuators serve as efficient, virtually maintenance-free, and are environmentally friendly alternatives compared to its hydraulic or pneumatic counterparts. They can be self-contained in aluminum, zinc and/or polymer housing making it very compact in size. Linear actuators are also ready to mount for easy plug-in operations. Actuators with modular design and open architecture offer opportunities to choose and integrate components to achieve customized solutions within existing envelopes. Application potential expands with the introduction of technologies for specific purposes, such as hall sensors, limit switches, potentiometer, friction clutches, or backup nuts. Screw-type linear actuators powered by an electric AC or DC motor basically consist of a lead screw with drive nut and push tube. In 90% of the cases, a gearbox between the motor and the screw is also present. When power is supplied, the motor rotates the lead screw, which causes the drive nut to travel and extend the push tube. Reversing the motor rotation retracts the push tube.

Mech Value Linear Actuators

Smaller Mech Value linear actuators or electric cylinders of the Automationware manufacturer are distinguished by high performance in terms of travel speed and load capacity, as they have integrated precision ball screws. The Mech Value linear actuator may be used as a replacement for a pneumatic cylinder in cases where precise control of travel speed and position is required.

They are equipped with innovative stepper motors with an encoder or in the Sensorless version, which represents a new electric actuator control technology and allows to determine the correct position without installing the encoder, reducing the cost and required actuator sizes.

The profiles of the electric cylinders or actuators are designed to allow the integration of the AwareVu sensor (Industry 4.0) to detect vibrations and increased temperatures and, consequently, to detect possible errors during the linear actuator operating phases.The motor may be mounted on the linear actuator in the same line or in parallel depending on the use and space constraints.

The Mech Value actuators are available in sizes 16 – 25 – 32. Standard strokes range from 50 mm to 500 mm (longer strokes are also available on request). The Mech Value linear actuator can be loaded from 50 to 1700 N and provides the precision of ± 0.02 mm.

Examples of use:

Packaging machines

Linear actuators are ideal for industrial purposes, such as packaging machines, where the need for high speed and precision travel arises.

Medical care and diagnostic machines and devices

The linear actuator can be very useful for micrometric movements in scanning devices. The linear actuator retains its position even in the event of a power failure. Compared to the hydraulic cylinder, the electric cylinders are more compact and thus more suitable for all portable devices. With their precision, linear actuators allow precise positioning of persons and objects in diagnostic devices.

Mech Line Linear Actuators

The reliable and popular Mech Line linear actuators are ideal for industrial use at medium loads. They are distinguished by their excellent price-performance ratio. The Mech Line linear actuators or electric cylinders are therefore a great alternative to pneumatic or hydraulic cylinders with extremely low operating costs.

With their long maintenance-free life and wide range of accessories, the Mech Line linear actuators are suitable for a very wide range of applications. They are available in four sizes, 25 – 32 – 50 – 63, and are ISO 15552 compatible.

Inside, there is a ball screw. The linear actuator can be equipped with a stepper motor or a brushless electric motor. The motor power can be transmitted directly or with a delay.

The Mech Line linear actuators are intended for standard operating strokes of 50 mm to 500 mm. An actuator with a non-standard stroke can also be designed if necessary. The Mech Line electric cylinder or actuator is suitable for loads from 0.32 kN to 14.6 kN.

Examples of use:

Pharmaceutical packaging machines

Linear actuators are also suitable for the use in pharmaceutical manufacturing cycles as they enable the manipulation of packaging in aseptic spaces. In addition, they are extremely accurate and require minimal maintenance.

Production automation

Linear actuators are indispensable in modern automated palletizing systems, in various production lines and automated warehouses. They can also be used to upgrade the existing machines and devices.

Mech Force Linear Actuators

The Mech Force linear actuator is suitable for the most extreme loads, as in cases where high dynamic loads occur over a longer period of time.

The aluminium profile of the linear actuator has a reinforced structure. The propulsion technology consists of customized ball screws, allowing for high dynamic loads and at the same time the optimum speed performance thanks to the various steps of the ball screw used in the linear actuator. The dynamic load capacities of the ball screws used are among the highest on the market, ensuring superior quality and top linear actuator performance.

The Mech Force linear actuators or electric cylinders are ISO 15552 compliant. They are powered by brushless or stepper motors, which can be connected to a linear actuator via a reducer to achieve a more compact design, and they consequently take up less space.

Actuators can also be equipped with the AwareVu diagnostic system, which ensures continuous feedback on the operation of the linear actuator. This provides timely information on the required maintenance or repair of the actuator.

The Mech Force 150 linear actuator version has a steel base structure.

Standard strokes range from 50 mm to 1000 mm. Typical actuator load capacities range from 1.88 kN to 190 kN.

Examples of use:

Aeronautical and military industries

Numerous military applications require industrial drives, such as linear actuators, which provide an excellent level of quality and ease of use in conventional applications.

The Automationware linear actuators perform excellently in a variety of configurations, such as navigation simulators. They are also suitable for outdoor logistics applications as they are also available with the IP65 protection.

Energy industry

The linear actuator has a wide range of applications in the energy industry as well. It is used for regulating the flow in hydroelectric power plants because it enables simple installation and regulation. In wind farms, they are useful for changing the incidence angle of the blades. Linear actuators are used in oil extraction or fuel production plants due to their easy maintenance and the possibility of remote control.

Mech Plus & Extreme Linear Actuators

Mech Plus & Extreme represent the most powerful linear actuators available. The Mech Extreme version is suitable for dynamic loads exceeding 750 kN. They are characterised by their exceptional durability based on a special ball screw system made according to the Automationware specification.

Because of this, linear actuators are suitable for the most demanding applications where high forces and/or prolonged operation occur. The dynamic load capacity of linear actuators is among the highest on the market, ensuring superior quality and drive performance.

In addition, actuators have a connector for the lubrication of the ball screw even for the cases where automatic lubrication is required.

In the case of parallel mounting, the linear actuator motors are interconnected via a slack-free belt transmission. The basic profile of the linear actuator has a reinforced structure to ensure maximum performance.

The entire series of the linear actuators is ISO 15552 compliant and they can be motorized with brushless or stepper motors, together with reducers, to minimize the dimensions and offer a compact solution.

The actuators are available with the AwareVu diagnostic device, which provides continuous monitoring of feedback on the linear actuator operation and warns of any unusual vibrations in advance. Connection is also possible via Wi-Fi.

In this manner, the Mech Plus series adds the Industry 4.0 technology and compactness as a standard.

Standard strokes for Mech Plus & Extreme range from 50 mm to 1500 mm. Load capacities range from 3.4 kN to 752 kN.

Examples of use:

Automotive industry and heavy cargo movements

The automotive industry often requires the use of hydraulic cylinders in the production line and in the component assembly phase, where they are used as a part of the press. By using linear actuators instead of hydraulic cylinders, you avoid the complex pneumatic or hydraulic installations, as the linear actuator makes installation and programming easy.

Machine tools

Linear actuators are used as a substitute for hydraulic systems in sheet metal bending machines. The ease of use and simplification of systems are highly welcome in applications that require any sort of pressing of the material. They are thus used in machines for inserting tires, for the production of springs and for bending sheet metal. Linear actuators are also suitable in cases where there is a need to insert mechanical components, such as bearings, bushings, rings and similar.

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

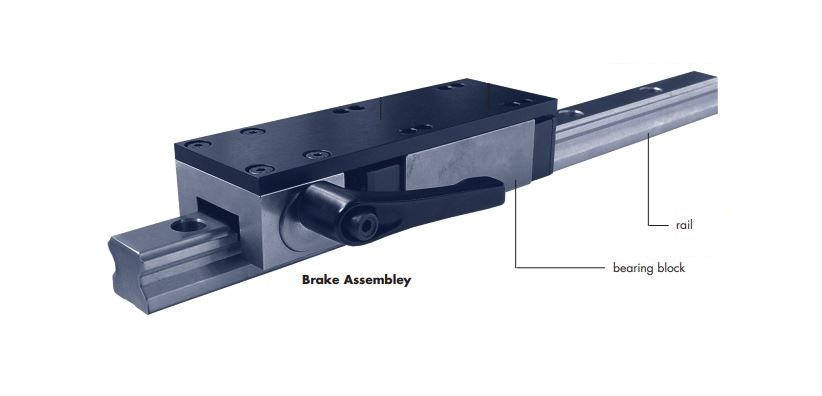

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...