GFX HepcoMotion Guidance System for Beckhoff XTS Transport System

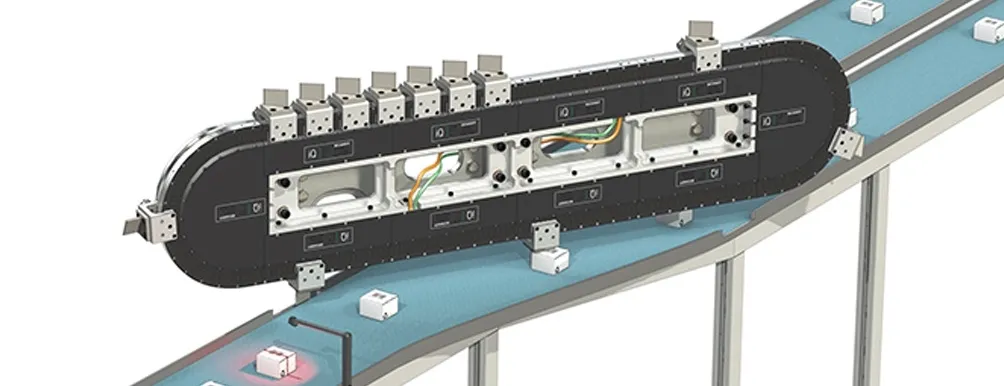

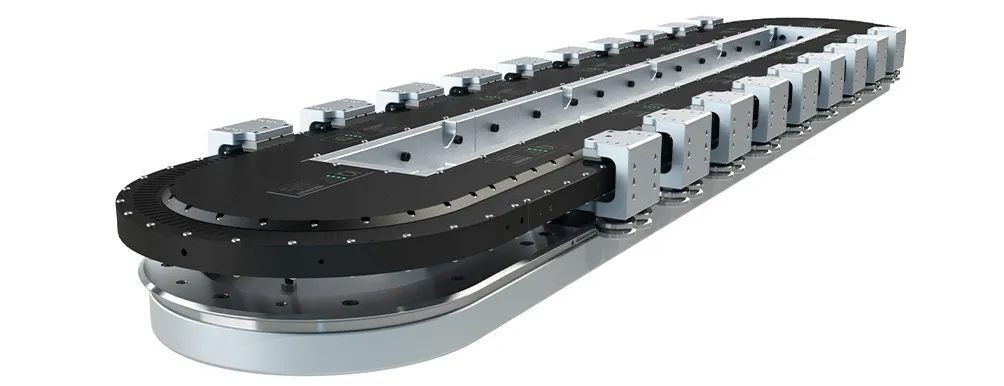

The GFX Hepco Guidance System for Beckhoff XTS Transport System employments direct servo engine innovation to drive movers around a track. The movement of each mover is autonomously controlled, advertising complex high-speed movement profiles without compromising positional precision. Combined with HepcoMotion’s demonstrated track systems, the profoundly flexible item is quickly being used inside the packing and manufacturing businesses as clients advantage from endlessly improved production rates with the capacity to create on the fly item changes.

HepcoMotion GFX system together with Beckhoff XTS is appropriate for load range 0-50 N and speeds up to 4 m/s.

The GFX Hepco Guidance System for Beckhoff XTS accommodates higher duty XTS applications where movement profile and long term endurance necessities are especially challenging.

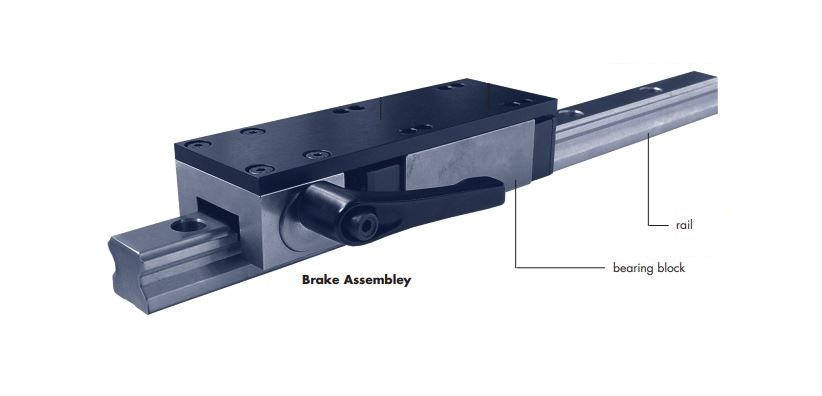

- Reinforced steel guidance system (PRT2 or 1 -Trak) holds exactness over long periods

- Disentangled lubrication system – allows use in high duty cycle manufacturing environments

- Lightweight mover assembly incorporates large capacity HepcoMotion V bearings

- V bearings grease packed for life

- Reduced maintenance Drain lubrication system for the track – nourishment applicable lubricants can be utilized if needed

- Simple change mover system with detachable track segment and movers

- Stainless steel guidance system accessible for nourishment processing applications

| Send Inquiry! | info@tuli.si |

PERTINENT CASE STUDIES & INDUSTRY SOLUTIONS

- Beckhoff’s XTS and HepcoMotion’s imaginative GFX boosts effectiveness and adaptability in an optical testing machine for airbag diffusers

The client's objective was to attain a medium cycle time of under two seconds, in spite of there being 15 processes of changing lengths. Another challenging component of the plan was the moderately high weight of the mover – around 4 kg. In order to have the ability to control the diffusers for all-round review, the movers had to be prepared with lifting and rotation instruments. An extra and vital factor was the durability and reduced maintenance of the system to ensure negligible downtime of the system, which performs in a three-shift operation. The ultimate plan of the new automatic optical review system included a total track length of 11 meters, on which 35 movers travel at the same time through 15 assessment stations.

- Reduced maintenance bundling arrangement for printer cartridges permitting on the fly item changes

When Dutch machine builder Smart Automation was commissioned by one of the world’s most-known driving printer cartridge producers to create a machine that completely computerizes the bundling of a wide assortment of cartridges, it was basic to construct a strong and persistent cell. The specification required the machine to process six standard setups of bundling formats and compositions, counting four different combinations of printer cartridge. It was moreover vital to offer the capacity to switch between setups inside a matter of minutes. The ideal best speed was decided to be 2.13m/s, with a load of 0.293kg and a finger length of 52mm.

- HepcoMotion GFX guidance system for Beckhoff XTS utilized for high duty packaging application uses reduced maintenance arrangement offering high reliability

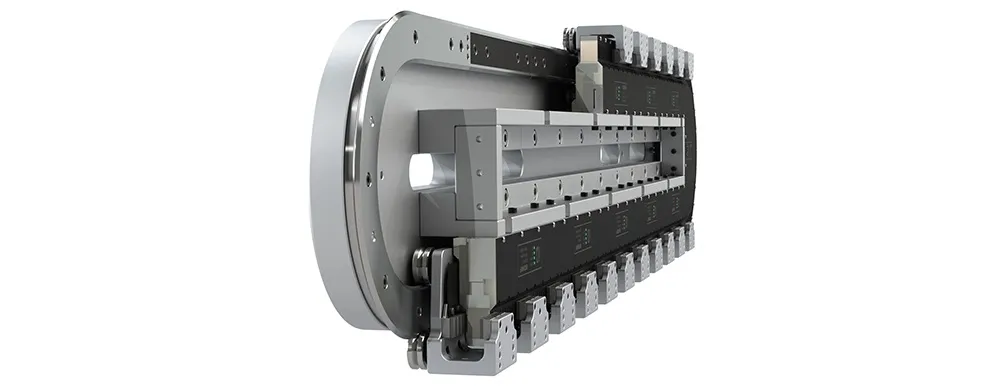

For its new development, the Pickfeeder Twin 200 unscrambler system, linear movement master HepcoMotion was challenged to realize a cycle of 200 containers per minute, whilst also guaranteeing high reliability and reduced maintenance. The technical specification of the application required a load of 0.5 kg for the weight of the item, plus the uncommon plan clamp and its relative position concerning the movement of the diverse segments of the circuit. The full perimeter of the circuit is 3.5 m, counting the straight areas for 5 x Beckhoff motors, additionally 2 x 180º curves. The circuit is mounted at 45º to overcome the forces of gravity within the return of the movers. With a cycle time of 2.4 seconds in an anti-clockwise heading, the system must work 16 hours a day, 7 days a week with an ensured life of 2 years. Given the high kinematics of the application, with speeds of 3 m/s, increasing speeds of up to 30 m/s2, as well as the 45º mounting orientation, the application is challenging and Packfeeder required HepcoMotion to plan and fabricate a new circuit with diminished weight movers and low friction, without compromising the carrying capacity, hardness, and accuracy of the system. READ MORE