From a wide range of linear guide rails and linear blocks in Tuli offer you can always find the best solution for your machine. You can choose from different types of guides and blocks from different premium producers such as Bosch-Rexroth, INA, THK, HepcoMotion, NSK, Hiwin, Schneeberger, WON, PBC and from our low-cost offer of Economy brand.

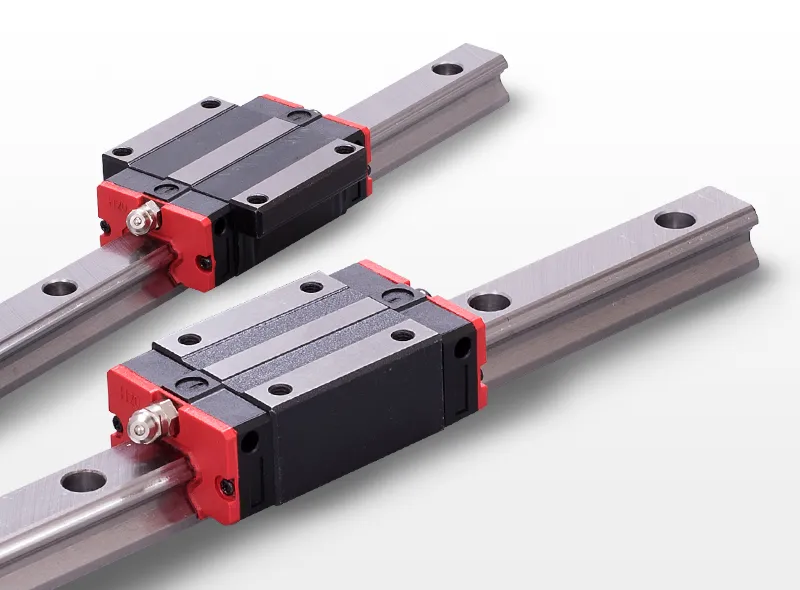

Ball guides

One of the most popular items are precision ball linear guide rails which are suitable for most demanding applications of linear motion movements as they occur in CNC machines. You can choose from different classes or precisions and preloads. To suit your linear motion demands we offer different types of linear blocks: normal, slim line and flanged type linear ball bearings. Linear rails and guides can be cut to the required length.

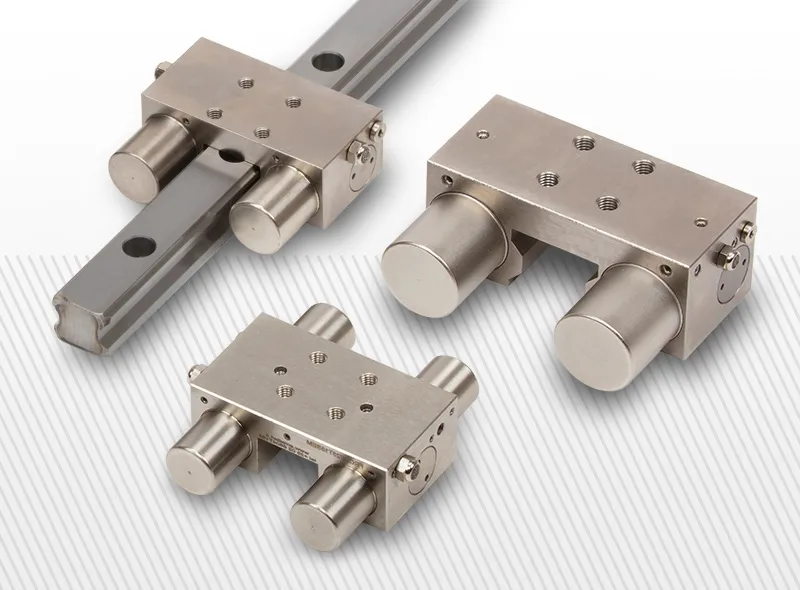

Miniature guides

We offer linear miniature guides and blocks with balls of a sliding type. Ball-type miniature linear guides have a structure where two raceways are incorporated into the compact body, enabling the model to receive loads in all directions and to be used in locations where a moment is applied with a single linear rail. They are typically made from stainless steel. Sliding-type linear guides require little maintenance and provide an interchangeable alternative to recirculating linear guides. This linear system is self-lubricating, dampens vibration and tolerates shock loads. Sliding linear bearings will not fail catastrophically. They are designed to operate in high or low-temperature conditions.

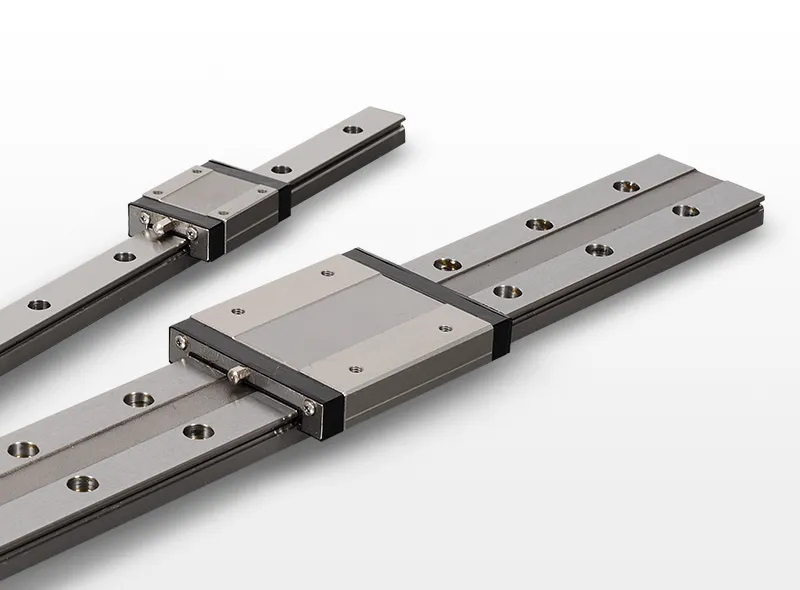

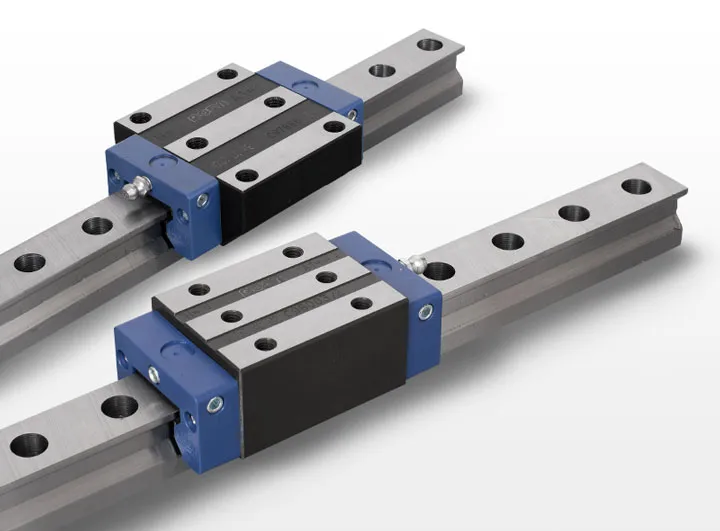

Roller guides

Linear roller guides and blocks are suitable for high load and high rigidity demands. They are used for machine tools, industrial robots and general machine building which require compact, roller linear guides in various accuracy classes.

Roller bearing guides

The roller bearing guides and blocks are very robust and simple linear guides. You can select linear bearing rail from CTS, Radia and HepcoMotion. V groove roller bearing and linear bearing rail from HepcoMotion offer a unique wiping action which expels debris, keeping machines running and reliable.

Combined bearings systems

Combined bearings systems are ideal for heavy-duty applications that have very high radial and axial loads and do not have a demand for high precision. Individual linear/rotary bearings can sustain loads of up to 140 kN. Equally robust are the U or I section rails available in 20 sizes up to 12 m long. Fully assembled handling systems with a range of drive systems are suitable for loads up to 50 tonnes.

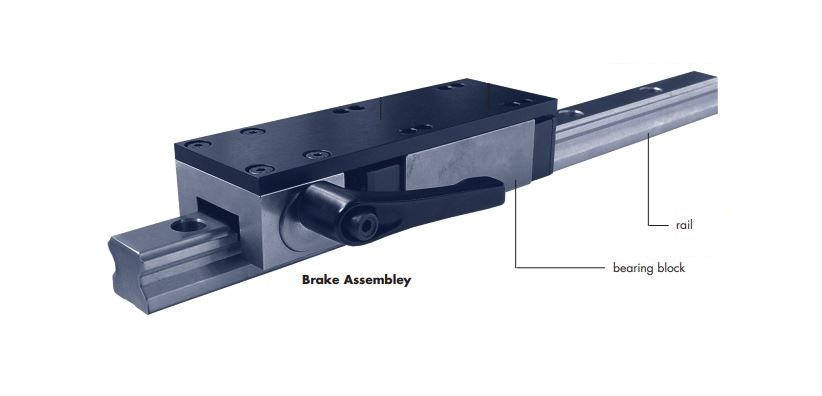

Clamping brakes

Clamping brake provides a compact and simple method of locking a linear ball bearing block in position. The manual brake with a clamping lever is intended for the manual locking of a stationary block. The pneumatic version can be implemented into the automation system so the block can be fixed on the rail with remote control.

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...