Aluminum Extrusion Brackets

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for creating strong and versatile structures thanks to their light weight, great strength, and corrosion resistance. From U8 and U10 aluminum brackets to inner and outer angles, there is a diverse range of aluminum extrusion brackets available which make them useful for many applications. Common aluminum extrusion brackets applications include 3D printer enclosures, machine guards, custom furniture, solar panel stands, medical equipment stands, and many more.

Whether you're embarking on a DIY project or seeking solutions for industrial endeavors, understanding the capabilities of these brackets can unlock a world of possibilities from sturdy frames for 3D printers to sleek enclosures for electronics.

This comprehensive guide aims to shed light on the functionality, types, and applications of aluminum extrusion brackets, ranging from U8 and U10 aluminum brackets to inner and outer angles, and beyond.

Understanding Aluminum Extrusion Brackets

Aluminum extrusion brackets are integral components in modular construction and assembly systems, facilitating the creation of sturdy frameworks and structures.

By harnessing the lightweight yet robust properties of aluminum, these brackets provide reliable support while enabling flexibility and customization in design.

They typically feature slots or holes that align with the T-slots of the aluminium profiles, allowing for a secure and screw-based connection, thus allowing to join aluminum profiles at specific angles.

Exploring Different Types of Brackets

1. Aluminum Brackets

These brackets are commonly used for modular assemblies that require securing U8 or U10 aluminum profiles and providing additional reinforcement in various configurations.

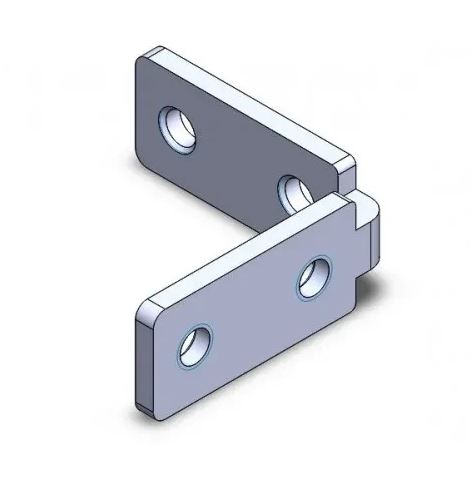

2. Inner and Outer Angles

Inner brackets are utilized to connect profiles internally, providing stability and support within framework assemblies. Outer angles, on the other hand, serve to reinforce joints and corners, enhancing structural integrity.

Figure 1 Inner Angle

3. Cube Connectors

Cube connectors enable the creation of multidimensional structures by connecting profiles at right angles, allowing for the construction of frames, enclosures, and modular furniture. They also come in different sizes.

4. Floor Brackets

Floor brackets provide a stable base for structures by securely anchoring profiles to the ground, ensuring stability and load-bearing capacity.

Figure 2 Floor Bracket

5. 3-Way Brackets

These brackets facilitate the creation of branching connections, allowing profiles to intersect at different angles and directions, expanding design possibilities.

To learn more about how these brackets work with aluminum profiles, check our Aluminium Profile Modular System Catalogue

Applications of Aluminum Extrusion Brackets

Aluminum extrusion brackets are the invisible hands holding countless structures together. Here's a glimpse into their diverse applications:

1. Machine Guards

In workshops and industrial settings, safety is paramount. Aluminum extrusions with floor brackets and connector angles can be used to build sturdy machine guards, separating operators from moving parts.

2. 3D Printer Enclosures

3D printers often benefit from enclosed builds to maintain consistent temperatures and improve print quality. Aluminum extrusions with strategically placed inner and outer brackets create sturdy frames for custom-sized enclosures.

3. Custom Furniture

Forget bulky, pre-made furniture! Aluminum extrusions with a variety of brackets (cube connectors, 3-way brackets) offer the potential to design and build sleek, modern furniture that perfectly fits your space. Coffee tables, bookshelves, and even display units can be constructed with this versatile system.

4. Retail Displays

Eye-catching retail displays are crucial for attracting customers. Aluminum extrusions with connector angles and inner brackets can be used to create shelving units, kiosks, and product displays that are both functional and visually appealing.

5. Event Booths

Need a portable and customizable booth for trade shows or exhibitions? Lightweight aluminum extrusions with brackets allow for quick assembly and disassembly of booths with signage and product displays.

6. DIY Robotics Projects

Robotics enthusiasts can leverage aluminum extrusions and brackets to build custom robot frames. The modularity of the system allows for easy adjustments and modifications, perfect for experimentation and innovation.

7. Medical Equipment Stands

Hospitals and clinics often utilize stands for monitors, medical devices, and computer equipment. Aluminum extrusions with floor brackets and connector angles provide a stable and lightweight solution for building these stands.

8. Solar Panel Mounting Systems

Sustainable energy solutions are increasingly important. Aluminum extrusions with adjustable floor brackets (like universal floor brackets) can be used to create sturdy mounting systems for solar panels, ensuring optimal sunlight exposure.

9. Exhibition Stands

Similar to event booths, exhibition stands require a balance of functionality and aesthetics. Aluminum extrusions with a variety of brackets can be used to create interactive displays, information kiosks, and product demonstrations for trade shows and conferences.

10. Greenhouses and Garden Structures

The lightweight nature of aluminum extrusions makes them suitable for building greenhouses and garden structures. Frames can be constructed using extrusions and connected with inner and outer brackets, offering a customizable and durable solution for plant enthusiasts.

These are just a few examples, and the possibilities are truly endless. With the right combination of aluminum extrusions and brackets, you can bring your creative ideas to life in countless ways.

Figure 3 Brackets for aluminium profile

Advantages of Aluminum Extrusion Brackets

1. Lightweight

Aluminum's low density makes extrusion brackets lightweight yet strong, facilitating ease of handling, transportation, and installation.

2. Strength

Brackets reinforce connections between extrusions, creating a rigid and stable structure.

3. Corrosion Resistance

Aluminum extrusion brackets are inherently resistant to corrosion, ensuring long-term durability and minimal maintenance requirements, even in harsh environments.

4. Customization

With a wide range of profiles, sizes, and configurations available, aluminum extrusion brackets allow for customization to suit specific project requirements, enabling creative design solutions.

5. Modularity

Modular construction systems based on aluminum extrusions and brackets offer scalability and adaptability, allowing structures to be easily modified or expanded as needed.

6. Ease of Assembly

No welding or complex machining is required. Brackets simply slide into the T-slots and are secured with T-nuts and screws.

7. Versatility

A wide variety of bracket designs cater to different connection needs.

Choosing the Right Bracket for Your Needs

Selecting the appropriate bracket depends on your project's requirements. Here are some factors to consider:

1. Type of Connection

Do you need a 90-degree corner, a three-way connection, or something else?

2. Aluminium profile extrusion Size

Match the bracket to the specific size (U8, U10, etc.) of your aluminum extrusions.

3. Load Requirements

4. Desired Aesthetics

Certain brackets like inside angles provide a clean look, while outside angles might be more suitable for industrial applications.

Tips and Tricks for Assembly Success

Here are some helpful pointers for using aluminum extrusion brackets effectively:

- Planning is Key: Sketch your project beforehand to determine the type and quantity of brackets needed.

- Use the Right Hardware: Select the appropriate screws and threaded nuts for a secure connection.

- Tighten Wisely: Overtightening screws can damage the bracket or extrusion threads.

- Double-Check Alignment: Ensure your extrusions are properly aligned before tightening the bracket.

Conclusion

In conclusion, aluminum extrusion brackets represent versatile solutions for a multitude of applications, offering strength, versatility, and customization options.

From U8 and U10 aluminum brackets to inner and outer angles, cube connectors, and more, these components empower designers, engineers, and DIY enthusiasts to realize their creative visions while ensuring structural integrity and performance.

Whether in DIY projects, industrial settings, or commercial construction, aluminum extrusion brackets serve as indispensable building blocks for innovative and functional structures.

Leave a Comment

Your email address will not be published. Required fields are marked *