Types of Bearings

Bearings are fundamental components in machinery, enabling smooth motion and reducing friction in a wide range of applications. Dive into the world of bearings with this comprehensive guide exploring various types, including radial ball bearings, radial roller bearings, thrust bearings, and more. Learn about the unique features and applications of each type, from providing smooth rotational motion to supporting heavy axial loads. Whether you're a mechanical engineer or a DIY enthusiast, this guide offers valuable insights into the different types of bearings and their functionalities.

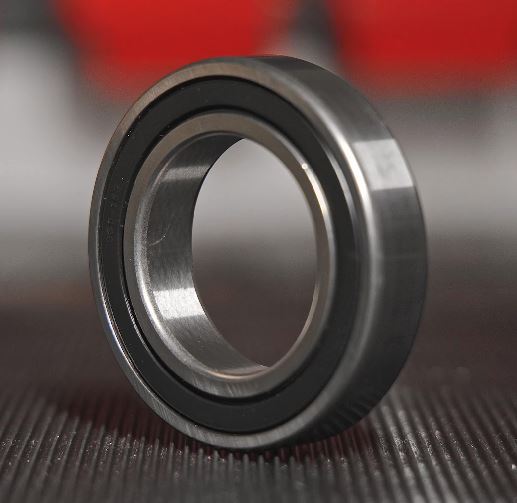

Radial Ball Bearings

Radial ball bearings are among the most common types of bearings, featuring balls arranged in a circular raceway within the inner and outer rings. They are designed to support radial loads while allowing for smooth rotational motion in a variety of machinery.

Main Applications:

- Electric Motors

- Pumps and Compressors

- Conveyor Systems

- Automotive Wheels and Transmissions

- Household Appliances

Figure 1: Radial ball bearing

Radial Roller Bearings

Radial roller bearings utilize cylindrical or tapered rollers instead of balls to support radial loads. These bearings offer higher load-carrying capacity compared to ball bearings, which makes them suitable for applications where heavy radial loads or combined radial and axial loads are present. They provide increased stability and durability in demanding environments.

Main Applications:

- Automotive Transmissions

- Industrial Gearboxes

- Heavy Machinery (e.g., Cranes, Excavators)

- Railroad Axle Boxes

- Mining Equipment

Figure 2: Radial roller bearing

Thrust Bearings

Thrust bearings are designed to support axial loads, facilitating rotation along the axis of rotation. They come in various configurations, including ball, roller, and needle thrust bearings. The main distinctive feature of these bearings is their ability to withstand high axial loads while maintaining minimal friction and ensuring smooth operation. However, thrust bearings cannot take radial forces.

Main Applications:

- Automotive Transmissions

- Machine Tools (e.g., Lathe, Milling Machine)

- Aerospace Systems (e.g., Aircraft Landing Gear)

- Marine Propulsion Systems

- Electric Power Generation (e.g., Turbines)

Thrust Roller Bearings

Thrust roller bearings feature cylindrical or tapered rollers arranged perpendicular to the shaft axis, allowing them to support high axial loads with minimal friction. The main distinctive feature is their capability to handle both heavy axial loads and shock loads, making them ideal for heavy-duty applications.

Main Applications:

- Crane Hooks and Winches

- Rolling Mills and Metal Processing Equipment

- Marine Rudder Systems

- Automotive Steering Systems

- Railroad Axle Boxes

Figure 3: Tapered roller bearing

Combined Axial Radial Bearings

Combined axial radial bearings, also known as angular contact bearings, are designed to support both radial and axial loads simultaneously. The main distinctive feature is their angular contact design, which enables them to accommodate high-speed operation and precise positioning.

Main Applications:

- Machine Tool Spindles

- Precision Instruments (e.g., Gyroscopes)

- Robotics and Automation Systems

- Aircraft Landing Gear

- Medical Equipment (e.g., X-ray Machines)

Plain Bearings

Plain bearings, also known as bushings or sleeve bearings, are simple bearings that consist of a cylindrical or flanged sleeve with a sliding surface. The main distinctive feature is their low-friction operation and maintenance-free design, making them ideal for applications where lubrication may be impractical or inaccessible.

Main Applications:

- Hinges and Pivot Points

- Sliding Mechanisms (e.g., Drawer Slides)

- Linkages and Couplings

- Bushings for Industrial Equipment

- Marine and Offshore Applications (e.g., Mooring Systems)

Figure 4: Plain bearing

Spherical Plain Bearings

Spherical plain bearings consist of an inner ring with a spherical sliding surface and an outer ring with a matching spherical surface. The main distinctive feature is their self-aligning capability, allowing them to accommodate misalignment and compensate for angular and axial movement.

Main Applications:

- Articulated Joints (e.g., Control Arms, Tie Rod Ends)

- Hydraulic Cylinders and Actuators

- Suspension Systems (e.g., Shock Absorbers)

- Agricultural Machinery (e.g., Tractor Linkages)

- Off-Road Vehicles and Recreational Vehicles

Linear Bearings for Round Shafts

Linear bearings for round shafts are designed to facilitate linear motion along a cylindrical shaft. They come in various configurations, including ball bushings, roller bushings, and sleeve bearings, and are used in linear motion systems. The main distinctive feature is their ability to provide smooth and precise linear motion with minimal friction, ensuring accurate positioning and repeatability.

Main Applications:

- CNC Machines and Machine Tools

- 3D Printers and Additive Manufacturing Systems

- Robotic Arms and Automated Guided Vehicles (AGVs)

- Medical Imaging Equipment (e.g., MRI Machines)

- Material Handling Systems (e.g., Conveyor Belts)

How to Choose the Right Bearing

Selecting the right bearing is crucial for ensuring optimal performance, longevity, and reliability in mechanical systems. With a multitude of bearing types available, each designed for specific applications and operating conditions, it's essential to consider several factors when making your choice. Here are key considerations, illustrated with examples, to help you choose the right bearing for your needs:

1. Load Requirements: Determine the type and magnitude of the loads the bearing will need to support. For example, in a conveyor system handling heavy loads, such as those in mining or material handling industries, radial roller bearings with high load-carrying capacity would be suitable.

2. Speed and Operating Conditions: Take into account the speed at which the bearing will operate and the environmental conditions it will be exposed to. For instance, in high-speed applications such as turbine engines or machine tool spindles, angular contact ball bearings with high precision and low friction would be necessary to withstand the rigors of operation. In harsh environments with high levels of contamination, such as agricultural machinery or construction equipment, sealed or shielded bearings with enhanced protection against dust and debris would be essential.

3. Accuracy and Precision: If precise positioning or high-speed operation is required, choose bearings with tight tolerances and high accuracy ratings. For example, in CNC machining centers or robotic arms requiring precise linear motion, linear bearings would be indispensable.

4. Lubrication and Maintenance: Evaluate the lubrication requirements of the bearing and the maintenance regimen it entails. For instance, in applications where regular maintenance is impractical or inaccessible, such as wind turbines or remote monitoring equipment, self-lubricating bearings with maintenance-free operation would be advantageous.

5. Mounting and Installation: Consider the ease of mounting and installation of the bearing, as well as any special tools or techniques required. In automotive repair shops or maintenance facilities, where quick turnaround times are essential, bearings with pre-assembled units or easy-to-install features would be preferable.

6. Cost and Availability: Balance the cost of the bearing with its performance and reliability requirements. For example, in critical applications such as aerospace or medical equipment, where downtime can have significant consequences, investing in premium bearings with extended service life and reliability would be justified.

7. Application-Specific Requirements: Take into account any specific requirements or constraints of the application. For instance, in off-road vehicles or agricultural machinery operating in rough terrain, bearings with robust seals and durable construction would be necessary to withstand shocks and vibrations. In linear motion systems such as 3D printers or automated warehouses, bearings with low friction and quiet operation would enhance efficiency and user experience.

By carefully considering these factors and consulting with experts, you can choose the right bearing for your application, ensuring optimal performance, reliability, and longevity in your mechanical systems. Whether selecting radial ball bearings for electric motors or linear bearings for CNC machines, making an informed decision will pay dividends in terms of efficiency, productivity, and overall system performance.

Some Final Thoughts

In conclusion, bearings are essential components in mechanical systems, providing support, reducing friction, and enabling smooth motion in a wide range of applications.

From radial ball bearings to thrust roller bearings, each type offers unique characteristics and advantages tailored to specific requirements.

By understanding the different types of bearings and their functionalities, engineers, designers, and maintenance professionals can select the most suitable bearings for their applications, ensuring optimal performance and reliability.

If you need bearings, trust Tuli Shop as your reliable provider. Contact us now and let us help you!

Leave a Comment

Your email address will not be published. Required fields are marked *