Thrust bearings

Thrust bearings consist of shaft-located washers, housing washers and cage balls. The bearings are demountable; the cage balls and the supporting washers can therefore be mounted separately. In addition to the series with flattened washers, there are also series with washers with a spherical outer surface, which allows spherical displacements and thus compensation for misalignment. These designs are typically used in conjunction with seat washers. Thrust ball bearings are available with both unidirectional and bi-directional axial load capacity. Both designs can support high axial forces but cannot be subjected to radial forces.

| For ADVANCED SEARCH of bearings go to: | Bearing configurator |

Thrust bearings with unidirectional load capacity

Axial or. thrust bearings with unidirectional load capacity can only support axial forces in one direction. They do not allow any oblique movement or misalignment between the shaft and the housing.

Offsetting of misalignment

The thrust bearings of the 532 and 533 series shall have a spherical shape of the outer part of the washer. With a suitable housing design and in conjunction with the U2 and U3 thrust washers, they allow for the adjustment of the bevel angle and can compensate for misalignment between the shaft and the housing.

Bearings with bi-directional load capacity

Axial ball bearings with bi-directional load capacity can support axial forces in both directions. The 522 and 523 series bearings have two flat washers for mounting in the housing and do not allow angular adjustments.

Offset compensation

The 542 and 543 series thrust bearings shall have a spherical chamfer on the outer part of the base. With a suitable housing design and in conjunction with the U2 and U3 series of shims, they can allow angular adjustments and can therefore compensate for axial misalignments between the shaft and the housing.

Operating temperatures

Thrust ball bearings can be used at operating temperatures from -30 °C to +120 °C and may be limited by lubricant.

Cages

Bearings with a steel sheet cage do not have a cage suffix. Solid brass cages are marked with the suffix MP.

Bidirectional thrust ball bearings

Bi-directional axial angular contact ball bearings are precision bearings, are demountable, and have limited dimensional tolerances (also available in SP class). They consist of positioning washers, a spacer ring, a housing for locating the washers, and a brass ball cage. The bearing parts shall match each other and may be inserted separately but shall not be interchanged with parts of other bearings of the same size.

Axial contact angular contact ball bearings

The arrangement of spindle bearings is subject to needs that often cannot be optimally met by ordinary bearings because of their design. To design maintenance-free or low-maintenance bearing arrangements for the highly dynamic operating conditions of precision spindles that have high load capacities, high rigidity and low friction, and are easy to install, INA/FAG produces a large range of angular contact axial ball bearings. With this highly developed product range, the best application-specific solution can be found for all technical and economic needs that arise for spherical roller bearings.

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

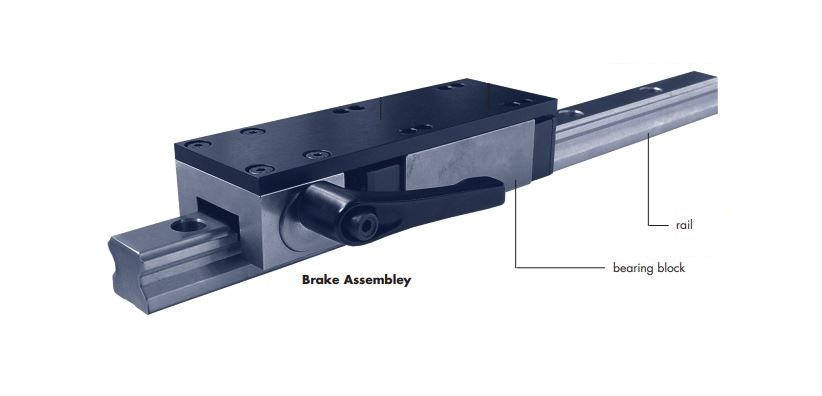

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...