Washers & strips

Washers and strips, also known as flat plain bearings, are fundamental mechanical components designed to minimize friction and wear between moving parts. Unlike ball or roller bearings, flat plain bearings have a simple, flat, and often rectangular or circular design. They are usually made of low-friction materials such as bronze, brass, or composite materials and in some cases require lubrication to operate efficiently.

| For ADVANCED SEARCH of bearings go to: | Bearing configurator |

Types of washers and strips

Rectangular Flat Plain Bearings: These flat plain bearings feature a rectangular shape and are often used in linear motion systems. They are designed for applications where stability and precision are essential.

Circular Flat Plain Bearings: Circular flat plain bearings are often employed in rotating machinery to reduce friction and distribute loads evenly. They come in various sizes and materials to suit specific applications.

The Role of washers and strips

Friction Reduction

The primary function of flat plain bearings is to reduce friction between moving parts. They achieve this by providing a low-friction interface between components, allowing them to glide smoothly and efficiently.

Load Distribution

Flat plain bearings play a pivotal role in distributing loads evenly across moving parts, preventing localized stress and wear. This even distribution is vital for extending the lifespan of machinery and ensuring its reliable operation.

Noise Reduction

The low-friction properties of flat plain bearings contribute to noise reduction in machinery, creating quieter and more efficient systems.

Applications of washers and strips

Automotive Industry

Flat plain bearings are widely used in the automotive industry, finding applications in components such as suspension systems, steering mechanisms, and engine parts. Their ability to reduce friction and distribute loads is essential for the smooth and reliable operation of vehicles.

Industrial Machinery

In industrial machinery, flat plain bearings are utilized in a wide range of equipment, including conveyor systems, pumps, and manufacturing machinery. Their capacity to withstand heavy loads and harsh conditions makes them indispensable in this sector.

Aerospace and Defense

The aerospace and defense sectors rely on flat plain bearings for their precision and reliability. These bearings are found in aircraft landing gear, control systems, and missile launchers, where performance and safety are paramount.

Advantages and Challenges

Advantages of Flat Plain Bearings

Flat plain bearings offer several advantages, including their simplicity, cost-effectiveness, and capacity to withstand heavy loads. Their ability to operate quietly and require minimal maintenance makes them a preferred choice in various industries.

Challenges of Flat Plain Bearings

Despite their many advantages, flat plain bearings are not without challenges. Some types require proper lubrication and periodic maintenance to ensure optimal performance. In some cases, misalignment or inadequate lubrication can lead to premature wear and failure.

Conclusion

Flat plain bearings may be unassuming in appearance, but they are integral to the world of engineering and machinery. These versatile components, available in various types and materials, contribute to reducing friction, distributing loads evenly, and ensuring the smooth and reliable operation of countless machines and systems. By understanding the types and roles of flat plain bearings, engineers and designers can make informed decisions, optimizing the performance of their projects while ensuring the longevity of their machinery and systems.

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

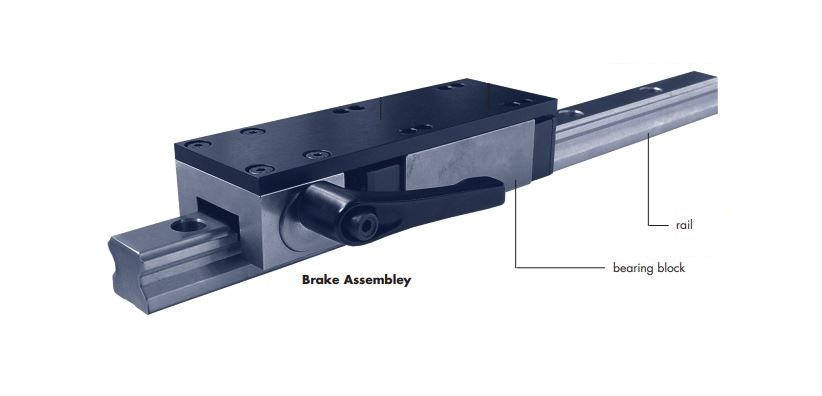

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...