Rod ends

In the world of mechanical engineering and machinery, various components play pivotal roles in ensuring smooth operation and functionality. One such crucial component is the "rod end." These bearing units that consist of a spherical plain bearing in the eye-shaped head of the rod end housing. They are essential for transmitting forces and motions in a wide range of applications. They are used primarily on the ends of hydraulic or pneumatic pistons to join the cylinder to an associated component via an internal (female) thread, external (male) thread or a welding shank.

| For ADVANCED SEARCH of bearings go to: | Bearing configurator |

What are Rod Ends?

Rod ends are mechanical connectors that facilitate motion and rotation within machinery. They consist of a spherical-shaped head that is attached to a housing or rod, allowing for articulation and movement in multiple directions. These components serve as crucial linkages in various mechanical systems, enabling the transfer of force, motion, and load.

Key Features of Rod Ends

They come with several key features that make them invaluable in engineering applications. Some of these features include self-lubrication, high load-carrying capacity, and the ability to compensate for angular misalignment. These characteristics ensure the efficient and reliable functioning of machinery.

Male and Female Rod Ends

Rod ends can be classified into two main categories: male and female. Male types have an external thread that allows them to be connected to other components using a bolt or stud. In contrast, female types have an internal thread that permits attachment to a threaded shaft or rod.

Standard and Heavy-Duty Rod Ends

Standard types are designed for general-purpose applications and have a compact size. They are suitable for light to moderate loads. In contrast, heavy-duty types are larger and sturdier, built to handle heavy loads and provide enhanced durability. Choosing the right type depends on the specific application requirements.

Maintenance-Free Rod Ends

Maintenance-free types are equipped with self-lubricating inserts or liners, reducing the need for constant maintenance and lubrication. These types are ideal for applications where accessibility for maintenance is limited or challenging.

Specialized Rod Ends

In addition to the standard categories, there are specialized types tailored to unique applications. These may include corrosion-resistant options, high-temperature, and precision types designed for extreme conditions and precision requirements.

Conclusion

Rod ends are integral components in the world of machinery and engineering. Their versatility and ability to facilitate motion, rotation, and force transmission make them indispensable in various applications. By understanding the different types and their unique features, engineers and designers can select the most suitable options to ensure the efficient and reliable operation of their machinery. Whether it's for a simple linkage or a complex mechanical system, these are essential components that contribute to the seamless functioning of countless machines and devices.

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

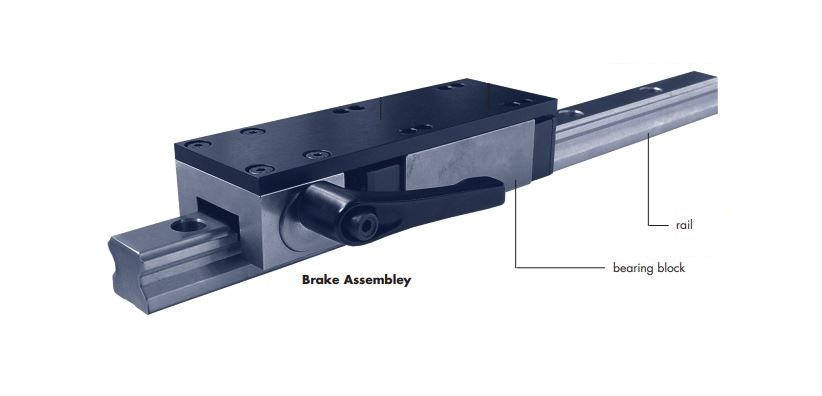

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...