Spherical plain bearings

Spherical plain bearings are self-aligning standardized bearings and enable multi-directional self-aligning movement. The inner ring has a spherically convex outer circumference, while the outer ring has a correspondingly concave inner circumference. They are suitable for static forces in cases where the bearing performs oscillating or repetitive tilting and rotating movements at relatively low speeds. The structural advantages of spherical sliding bearings are as follows: adaptability, elimination of edge stresses and excessive loading of adjacent components, adaptation to deformations of surrounding components during operation, adaptation to wide production tolerances, and the possibility of use in welded assemblies.

| For ADVANCED SEARCH of bearings go to: | Bearing configurator |

Spherical plain bearings are an excellent choice for cost-sensitive applications. They are available in a wide selection of designs, dimensional series and sizes that meet specific application needs. Regardless of whether the application requires a large or small sliding bearing, both are available and provide long service life, minimal maintenance and high operational reliability.

Spherical plain bearings are manufactured in standard dimensions and are readily available whenever and wherever needed. Economic aspects and unmatched design features are not the only reasons why spherical plain bearings are the best solution. Their design, materials and manufacturing quality enable a long service life and high reliability even in the most demanding applications.

Types of spherical plain bearings

1. Self-lubricating spherical plain bearings

Self-lubricating spherical plain bearings are mainly intended for cases where a long service life without maintenance and lubrication requirements is desired. They are also used in machine parts where lubrication would be difficult. In self-lubricating plain bearings, a PTFE-based self-lubricating liner is securely attached to the outer ring. Because there are no oil stains, the bearing is always clean. It is particularly suitable where forces act only in one direction or where the oscillation frequency is low. The inner ring is made of high carbon bearing steel and its sliding surface is hard chrome plated. For higher loads, a special type of spherical sliding bearing with an insert reinforced with steel mesh is available. All these types are suitable for temperature ranges from -50˚C to +100˚C.

2. Spherical sliding bearings with lubrication

Lubrication-type spherical plain bearings have sliding surfaces where both the inner and outer rings are made of steel. The outer ring has a single break for mounting. The absence of a mounting groove greatly increases the strength of the bearing. These bearings are particularly suitable for exposure to shock loads or alternating loads. The inner and outer rings are made of high carbon-bearing steel. After heat treatment and sanding, their surfaces are treated with a phosphate film, which makes them highly resistant to rust. In addition, their sliding surfaces are coated with molybdenum disulfide, which ensures very effective lubrication of the bearing in the initial operation phase. Both the inner and outer rings have an oil hole so that oil can be supplied from the shaft or the housing. The temperature range is from -50˚C to +150˚C.

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

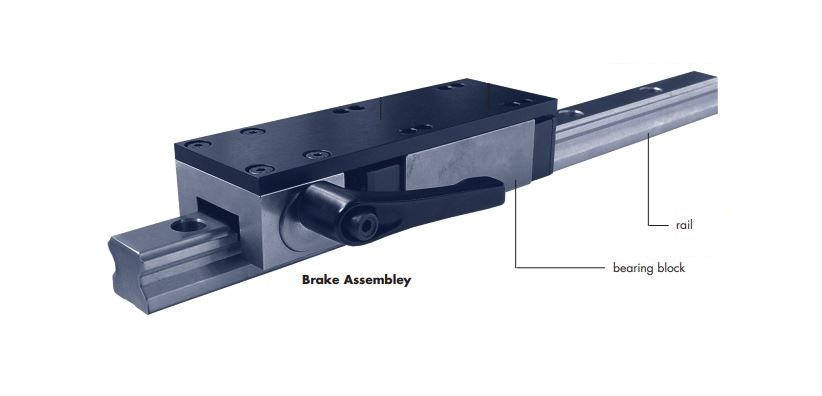

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...