Ring guides, track systems and segments

HepcoMotion provides an exclusive series of track systems, rings, ring segments, and ring disks. The rings and ring disks can be used as an advantageous substitute to slewing rings. Hepco track systems have notable benefits over conventional conveyor belt systems.

PRT2 Precision Ring Guides and Ring Segments

Load Range: 0-9300 N; Speeds: 0 – 5m/s

The PRT2 precision ring guides and ring segments are the latest invention for circular movement set up into a highly sophisticated range of ring systems and segments. The incredibly large series permits complete 360 degree, or segmental movement and guidance for a wide range of use in all industries. All components of the series are accessible in stainless steel materials, which allows the vast use of them in food, medical and scientific industries. Specific food lubricators and high temperature greases are accessible. The wide series of rings and ring discs provide an advantageous substitute to slewing rings.

| Send Inquiry! | info@tuli.si |

Ring systems have an integrated rack and pinion drive, or timing belt, thanks to which there is no need for supplementary drive elements.

Motion through an arc can be reached using ring segments – saving on two systems X and Y.

Large series of rings up to 1500mm diameter with high capacity V groove bearings and easy to use lubrication systems.

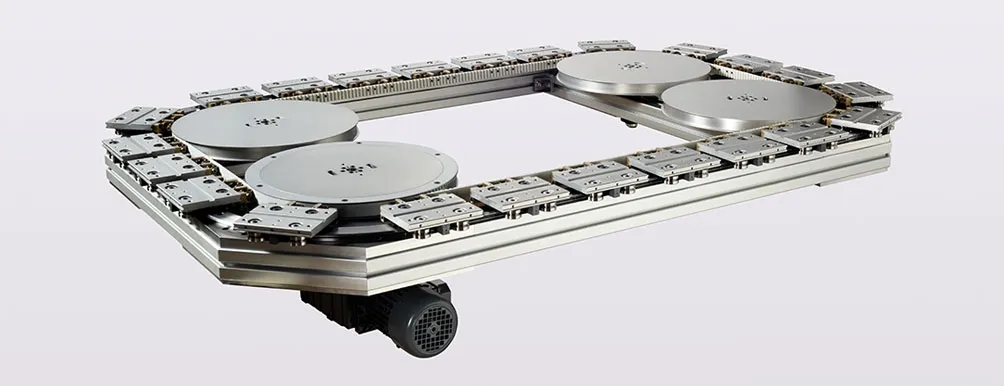

PRT2 Precision Track Systems

Load Range: 0 – 10000N; Speeds: 0 – 5m/s

PRT2 precision track systems are the latest invention for a combination of both circular and linear movement. Hepco’s Track Systems are accessible in oval, rectangular, and “S” bend configurations with multi carriages, which permits various assembly actions as part of one uninterrupted system. All components of the series are accessible in stainless steel, which allows the vast use of them in food, medical and scientific industries. Hepco’s track systems are an advantageous substitute to conveyer systems.

Track systems can be planned into “U” form, “J” form and many other forms.

Accessible with a variety of drive alternatives including belt, chain, scroll and many others.

Can run with or without lubrication.

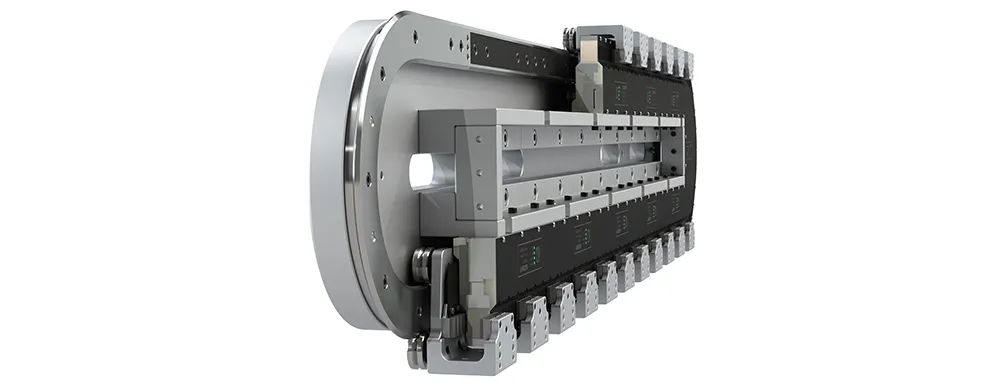

GFX Hepco Guidance System for Beckhoff XTS Transport System

Load Range: 0-50 N; Speeds: 0 - 4 m/s

The GFX Hepco Guidance System for Beckhoff XTS Transport System utilizes linear servo motor technology to drive movers around a track. The movement of each mover is separately managed, providing elaborate high-speed movement profiles without exposing positional precision. In combination with HepcoMotion’s certified track systems, the highly adaptable product is rapidly being taken in within the packaging and manufacturing industries as users profit from vastly enhanced production rates with the capacity to make on the fly product alterations.

The GFX Hepco Guidance System for Beckhoff XTS responds to the needs of higher duty XTS operations where movement profile and long-term endurance demands are particularly challenging.

Hardened steel guidance system (PRT2 or 1 -Trak) maintains precision over long time

Clear lubrication system – allows usage in high duty cycle production environments

Lightweight mover assembly contains high capacity HepcoMotion V bearings

V bearings grease packed for life

Low maintenance Bleed lubrication system for track – food compatible lubricants can be used if necessary

Easy change mover system with movable track section and movers

Stainless steel guidance system accessible for food processing operations

Read more about GFX Hepco Guidance System for Beckhoff XTS: https://www.tuli-shop.com/linear-motion-products/gfx-hepcomotion-xts-beckhoff

DTS Belt Driven Track Systems

Load Range: 0 – 400N; Speeds: 0 – 1m/s

HepcoMotion’s Belt Driven Track Systems are a complete package containing drive pulleys and belts together with all the additional mechanical parts necessary to make a system. Carriages are mostly built-in to the drive belt with a brilliant trip latch mechanism that separates and avoids damage in the case of system overload. A geared motor or index unit can be easily placed to the drive pulley. The belt driven track system is accessible with two dimensions of slide section (25mm and 44mm).

Tracks can include multi carriages that can be secured at workstations for precise assembly or positioning processes.

Simply included into a multi-function machine as a transfer or positioning system.

Track slides and end segments are built-in to indicate aluminium sections, the whole assembly can be mounted to your own installation.

Timing belt drive for more silent process than chain drives.

Possibility of buying individual DTS elements for planning into your own arrangement.

Large Diameter Ring Guides, Segments and Track Systems

Load Range: 0 – 220000N; Speeds: 0 – 2m/s

Hepco’s large diameter ring guides and track systems can be built in any diameter with no upper limit. Rings can be developed to your exact demands; in combination with Hepco’s series of V Guide bearings or MHD bearing blocks. More than 20 tonnes of load capacity can be performed.

Rings can be designated with a large mod gear and pinion drive, which allows extremely high driving forces.

Modular construction contributes to an easy assembly solution.

For greater rigidity rings can be provided tailored to matching back plates.

Lubrication system for bearing elements accessible as standard.

HDRT Heavy Duty Ring Guides and Track Systems

Load Range: 0 – 68,000N; Speeds: 0 – 4m/s

HDRT provides all the essential advantages of Hepco’s ring and track systems with the ability to carry much higher loads. Using certified elements, HDRT track systems are broadly utilized as transfer systems for machine tool and automation operations. In general automation, basic gear driven rings up to 1656mm diameter are a common solution. With little to no maintenance demanded, ring systems in many cases are seen as an advantageous substitute to conventional slewing rings.

150mm diameter V Groove bearings can be utilized for prolonged system life in high load capacity operations.

Track systems utilize certified heavy-duty double edge slides with built in parallelism, reducing the setting time.

Large carriage platform for simple and strengthen load location.

Built in lubrication utilizing bearing lubricators.

Gears machined directly into ring with matching pinions up to Mod 8 dimension for a high drive capacity.

All alternatives accessible in stainless steel.

1-Trak – Innovative Track System

Load Range: 0 – 28000N; Speeds: 0 – 8m/s

1-Trak is a highly innovative track system invention, which re-writes what is possible with linear and circular movement. Sophisticated materials and technologies are utilized to develop systems to nearly any two-dimensional form from one part of material. 1-Trak will reduce assembly time and permit “curvi” linear operations, earlier seen as expensive, to be reached in an easy simple way, with one drive.

Any imaginable 2D form can be performed; also, multi-dimensional curves and free-form curves are workable.

Track systems can be planned to your exact demands.

Carriages can be gear driven around the track, which cancels the require for elaborate drive systems.

System is built from one part of material with no separate linear tracks and segments to set up.

Where space is significant 1- Trak allows tight track return curves to be performed.

1-Trak can include a support for a machine, complete with drive and all fixing holes.

3 bearing carriage technology permits play free action throughout linear and circular travel.

Load capacities are only restricted by the maximum dimension of bearing at 150mm.

| Would you like to know more about Rotary and Continuous Motion Products? | Free Technical Help |

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

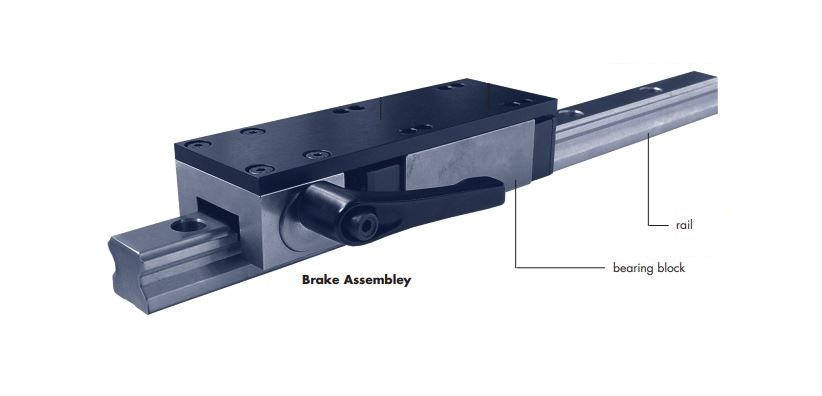

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...