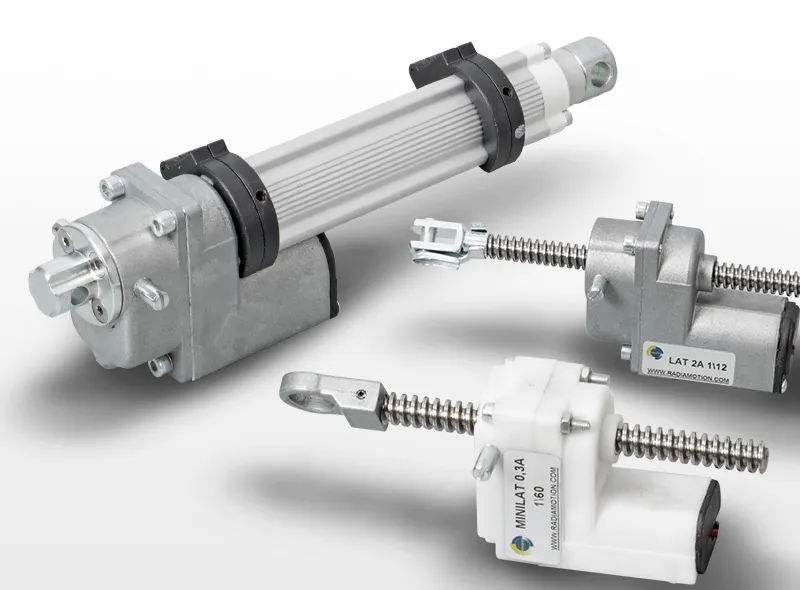

Electro-mechanical linear and rotary actuators enable precise, controlled, and repeatable movement in linear drive or rotational drive applications like pushing/pulling, opening/closing, clamping/gripping, tilting, rotating and raising/lowering.

Linear actuators serve as efficient, virtually maintenance-free, and are environmentally friendly alternatives compared to its hydraulic or pneumatic counterparts. They can be self-contained in aluminum, zinc and/or polymer housing making it very compact in size. Linear actuators are also ready to mount for easy plug-in operations. Actuators with modular design and open architecture offer opportunities to choose and integrate components to achieve customized solutions within existing envelopes. Application potential expands with the introduction of technologies for specific purposes, such as hall sensors, limit switches, potentiometer, friction clutches, or backup nuts. Screw-type linear actuators powered by an electric AC or DC motor basically consist of a lead screw with drive nut and push tube. In 90% of the cases, a gearbox between the motor and the screw is also present. When power is supplied, the motor rotates the lead screw, which causes the drive nut to travel and extend the push tube. Reversing the motor rotation retracts the push tube.

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

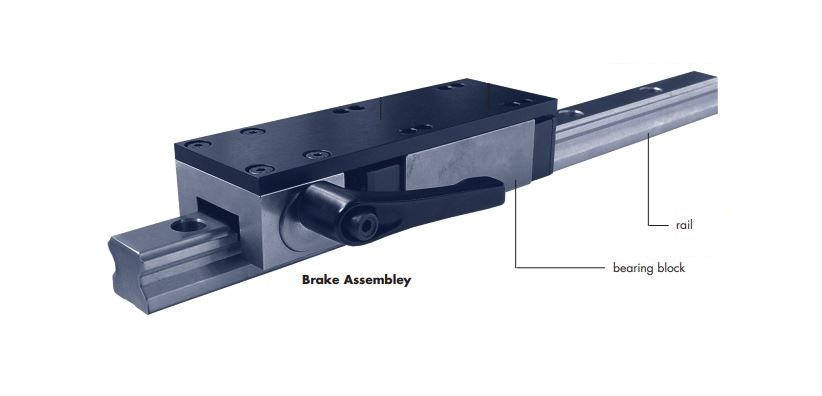

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...