Bearings sleeves

A rotating machine element such as a shaft is typically supported by two bearings, and locating these bearings on the shaft is a crucial part of the design, both for function and for assembly. Often, one bearing of the pair serves as the “locating bearing” and fixes the position of the shaft axially while the other bearing is free to move along the axial direction of the shaft.

Several strategies exist to locate the bearing and several factors have to be considered: the type and size of load the bearing will carry, thermal expansion and contraction when the machine is in operation, and the assembly and disassembly requirements. Bearings with a tapered bore are one option that designers use to solve the multi-faceting problem of bearing mounting, and when the tapered bore bearing is used on a straight shaft, bearing sleeves facilitate the mounting and dismounting of tapered bore bearings. Bearing sleeves can be divided into two categories: adapter sleeves and withdrawal sleeves.

| For ADVANCED SEARCH of bearings go to: | Bearing configurator |

Bearing adapter sleeve

The bearing adapter sleeve has a cylindrical bore to fit on a straight shaft, with a tapered outer surface to mate with the inner race of the tapered bore bearing. On the small end of the taper is a threaded section to receive a correspondingly threaded nut. The bearing sleeves are slipped over the end of the shaft with the small outer-diameter end closest to the shaft end. The bearing is then installed over the end of the shaft and onto the tapered adapter sleeve, and both are positioned at the mounting location for the bearing. Finally, the adapter sleeve nut is threaded onto the bearing sleeve and tightened with a hooked spanner wrench, drawing the bearing sleeve into the inner race’s tapered bore. The nut gets tightened until the bearing expands by an amount specified by the manufacturer. This deformation of the bearing sleeve secures it to both the shaft and the inner race of the bearing. Often, a toothed lock-washer is used to keep the adapter sleeve nut from backing out due to vibration when the machine is in operation. To distinguish the bearing adapter sleeve from the withdrawal sleeve, keep in mind that the adapter sleeve is drawn into the bearing taper during installation. The adapter sleeve has the advantage that it can be installed anywhere along a straight shaft.

Withdrawal sleeve

The withdrawal sleeve is similar to the adapter sleeve in that it has a cylindrical bore to fit on a straight shaft, but the threaded section is on the large end of the tapered outside surface of the sleeve. To use it, the bearing is located against a shoulder or cap on the shaft that immobilizes the bearing’s axial movement in one direction. The withdrawal sleeve is inserted onto the shaft and into the taper of the bearing that is constrained against the shoulder. Then a press is used to slide the withdrawal sleeve along the shaft and into the tapered inner race of the bearing. The withdrawal sleeve expands the inner race of the bearing a specified amount and also grips the shaft as a result of the pressing operation. Upon the need for removal, a special nut is turned onto the threaded section of the withdrawal adapter and as it is turned against the bearing’s inner race, the withdrawal sleeve slides along the shaft and is withdrawn from the bearing’s inner race.

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

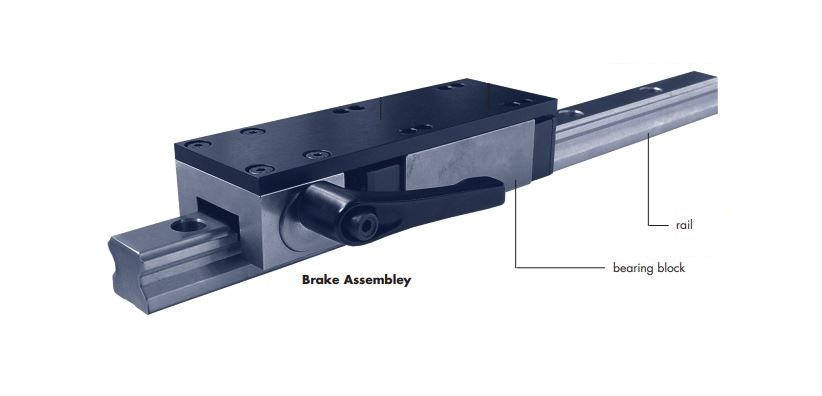

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...