Radial roller bearings

Roller bearings are indispensable machine elements used in many machines and devices. They have a higher load carrying capacity than ball bearings because there is linear contact between the roller and the ring of a bearing, whereas in ball bearings this contact is point contact.

These bearings utilize cylindrical, tapered, or barrel-shaped rollers to distribute the load evenly across the bearing surfaces. Below is a general overview of the common types of bearings with rollers.

| For ADVANCED SEARCH of bearings go to: | Bearing configurator |

Cylindrical roller bearings with cage

Single row cage cylindrical roller bearings are units consisting of solid inner and outer rings together with a cylindrical roller in a cage. The outer rings have rigid ribs on both sides or are ribless, the inner rings have one or two rigid ribs or are ribless. The cage prevents the cylindrical rollers from coming into contact with each other during rotation. Cylindrical roller types are very stiff, can support high radial loads and, because of the cage, are suitable for higher speeds than bearings without a cage. Bearings with the suffix E have larger roller assemblies and are therefore designed for extremely high load capacity. The bearings can be dismantled and can therefore be installed and dismantled more easily. The two bearing rings can therefore fit together.

High precision cylindrical roller type

These cylindrical roller bearings are precision double row bearings for machine tools. They provide radial rigidity, high bearing placement accuracy and are mainly used for radial support of main spindles. The bearings consist of solid outer rings without ribs, solid inner rings with three ribs and cylindrical rollers with brass cages. The cylindrical roller type of bearings can be disassembled and are therefore easier to install and remove. The two bearing rings can therefore fit together.

Cylindrical full roller type

Cylindrical roller bearings have solid inner and outer rings and cylindrical rollers which are guided inside the ribs. As these bearings have the maximum possible number of rotating elements, they have a high radial load capacity, high rigidity and are suitable for particularly compact designs. However, due to their kinematic conditions, they cannot achieve the high speeds that can be achieved using cylindrical roller type of bearings with a cage. Cylindrical full roller types are available in non-located, semi-located and located forms, and in single-row and double-row forms.

Cylindrical roller type with spring ring grooves

Cylindrical roller bearings with spring ring grooves are sophisticated units consisting of solid inner and outer rings, cylindrical rollers guided by ribs and sealing rings. The outer rings have grooves for the attachment of the spring rings or coil springers. The inner rings are axially separated, 1 mm wider than the outer rings, and held together by a steel band twisted in the appropriate place.

Locating bearings

Cylindrical roller types with grooves for the spring rings are locating bearings. These bearings are very stiff and can support axial forces in both directions as well as high radial forces. Due to their fully cylindrical design, these bearings have the highest possible number of rotating elements and therefore extremely high basic dynamic and static load carrying coefficients. However, due to kinematic conditions, they cannot achieve the high speeds that can be achieved using cylindrical roller types of bearings with cages.

Bearings for cable harnesses

The grooves in the outer ring make the bearing rings simply axially located. The bearings are therefore very suitable for the bearing arrangements of cable harnesses.

Tapered roller bearings

Tapered bearings are characterised by their high radial and axial load capacity, and a large and usable speed range. They are effective in supporting loads and providing accurate and rigid guidance of the shaft system due to the large and effective clearance between bearings. They are flexible, can be dismantled and can therefore be easily installed.

Spherical roller bearings

Spherical bearings are double row bearings consisting of an outer ring with a concave channel, an inner ring and barrel rollers in a cage. The inner rings may have cylindrical or tapered bores. The symmetrical barrel rollers are themselves symmetrically arranged around the convex outer channel of the ring. As a result, shaft deflections and bearing seat misalignments are compensated.

Barrel roller bearings

Barrel roller type of bearings are single row, flexible bearings. They consist of a solid outer ring with a concave channel, a solid inner ring with two ribs and a cylindrical or tapered bore, and barrel rollers in a cage. The bearings cannot be dismantled. Barrel roller type of bearings are particularly suitable in situations where high radial loads are encountered and it is necessary to compensate for irregularities such as misalignment. The axial load capacity is low. Tapered bore bearings have a taper of 1:12 and a suffix K. These bearings are also accessible for mounting with quick mounting bushings. Quick mounting bushings are included in the catalogue dimension tables and are ordered separately.

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

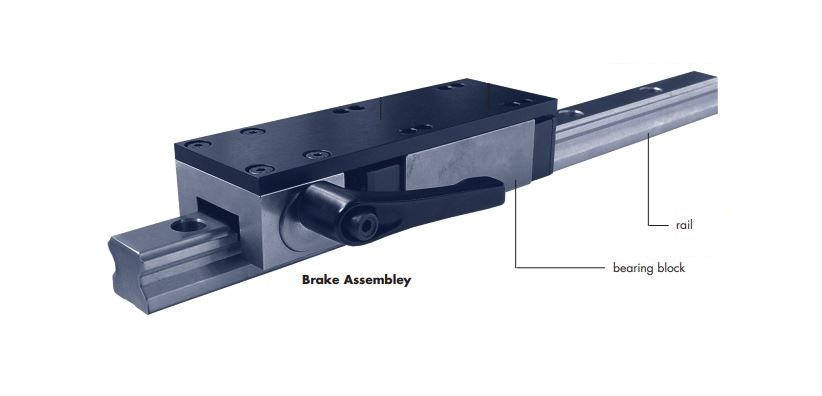

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...