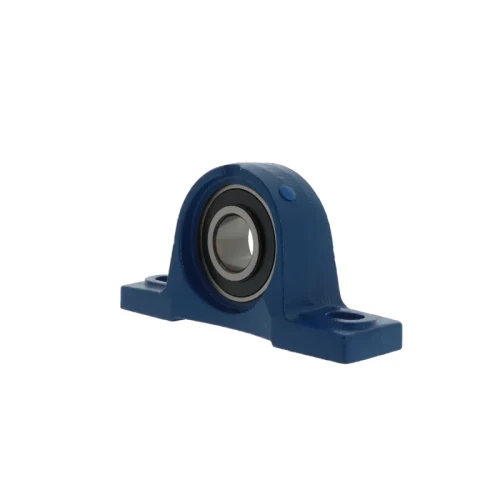

Bearing housings

Bearing housings solve the challenge of mounting, supporting, and aligning your bearings as well as shielding the bearing from contaminants. They can also contain lubrication and increase the service life of the bearing. Plummer block housings (also called pillow block housings for applications of low speed or light weight) make for straightforward pedestal mounting of bearings intended to have a stationary outer race and rotating inner race. They are typically used for mounting rotating shafts to a support structure. The housing mounts to the structure through the clear holes in the bearing housing, and the bearing is captured in the housing using either set screws, snap rings, or in some cases the housing is designed to capture the bearing without any separate hardware.

| For ADVANCED SEARCH of bearings go to: | Bearing configurator |

Types of bearing housings

Our housings come in two types depending on the design for assembly: split block housings are used when access to the end of the shaft is limited, so these can be assembled around the middle of a shaft and fit over a bearing already installed on the shaft. Single piece housings are intended to be slipped onto the end of the shaft either with the bearing already in the housing, or over the bearing already installed on the shaft. In both cases the inner race of the bearing is a slip fit on the shaft and usually made fast on the shaft with a set screw. Housings that come with a bearing installed in them are sometimes referred to as housed bearing units or cartridge housings.

Aside from their use as a mounting solution, they provide a sealing function to keep dust, dirt, and other contaminants out of the rolling elements of the bearing. Some types include a grease fitting that promotes preventative maintenance operations.

Materials bearing housing

Housings for bearings are typically made from durable materials such as cast iron or ductile iron, ensuring their ability to withstand heavy loads and harsh environments. Some specialized applications may require exotic materials like stainless steel or aluminum alloys for enhanced corrosion resistance or weight reduction. When alignment is critical, the housing for bearings often features a precision bore.

Benefits of bearing housings

Bearing housings offer the following benefits for cost-effective machine design:

- Extended Bearing Life: By protecting bearings from contaminants and providing a stable mounting surface, they significantly extend the lifespan of the bearings they encase.

- Enhanced Performance: Housings ensure proper bearing alignment and prevent excessive vibration, contributing to smoother operation, reduced noise, and improved efficiency of the rotating machinery.

- Reduced Maintenance Costs: By minimizing bearing wear and tear, housings for bearing help lower maintenance costs associated with bearing replacements and repairs.

- Increased Reliability: They play a critical role in preventing bearing failures, which can lead to costly downtime and disruptions in operations.

Applications of bearing housings

Typical applications for plummer block bearing housings include agricultural machinery, conveyor belt assemblies, industrial automation, food and beverage packaging, automotive, and aerospace.

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

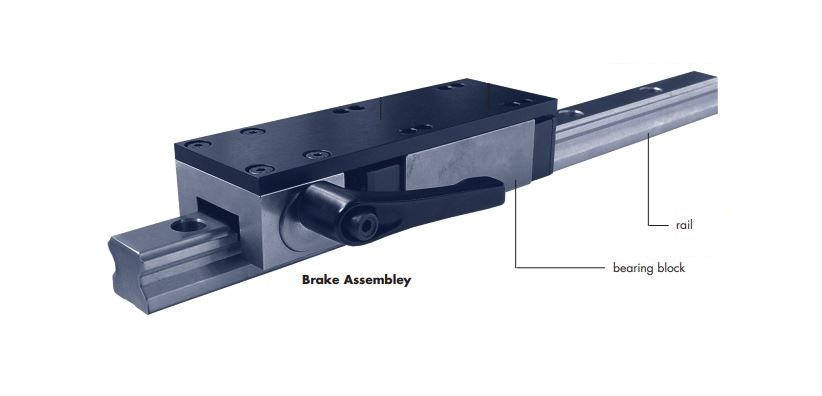

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...