Spline shaft and ball bushing

The design of TBI ball spline utilizes the friction force through the contact of the steel ball within the spline nut and the grooves on the spline shaft. With TBI-MOTION`s unique 40-degree angular contact design which enables the ball spline to deliver on its praiseworthy ability of extremely high load carrying capacity. The concept is optimal for the application involving high speeds, intense vibrations, impacts of loading sequences and precise positioning requirements. Also when the ball spline is used to function as a linear bushing, the ball spline provides 10x the loading capacity compared to the ordinary linear ball bearing bushing sharing similar dimensions but with a more compact profile. Namely, durability and reliability are the main reasons for choosing TBI ball spline for your machine applications.

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

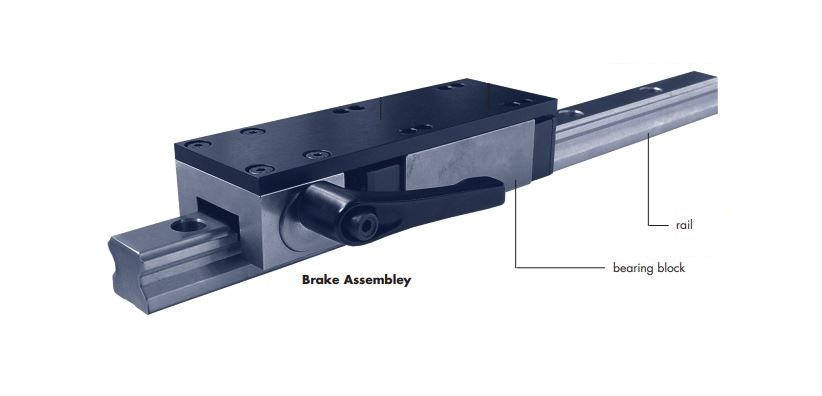

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...