Ball screw preloads

Preloading a ball screw nut is used to increase the accuracy and rigidity of a ball screw system. In many applications involving ball screw technology, there is great emphasis on positioning and precise movements. Any deviations could compromise the desired outcome. Since most ball screws have a clearance or backlash due to the design of the balls between the groves it is advisable to apply a preload to eliminate such hindrances. A preload makes the system more rigid by creating a load between the ball screw nut and shaft, which reduces structural displacement when under an external force. As to the amount of preloading, one should be cautious to prevent unnecessary friction and heat generation throughout the ball screw’s expected lifespan.

| Buy Ball Screws Online! | Online Shop |

Ways to achieve preload for ball screw systems

There are a number of ways to achieve preload for ball screw systems, with the most popular being the use of oversized balls located within the ball nut. Adjustable ball nuts and double-nut systems are also common solutions in the industry.

The oversized ball method is a relatively low-cost option and can be achieved with a variety of nut styles. This method works by loading oversized balls into the ball nut which eliminates the clearance between the screw and nut raceways (all ball nuts in our store are like this and are sold with a 2% preload).

For applications where preloads do not need to be precise or when it should be variable for optimization purposes, an adjustable nut is an option. A special screw can be used to adjust the internal diameter of the nut, eliminating clearance and increasing the preload. The adjustable nut method is inexpensive and allows flexibility where other methods do not. The downside of this method is, of course, its inability for precise preloads. It is ordinarily found in applications where rigidity is important, but not extremely critical.

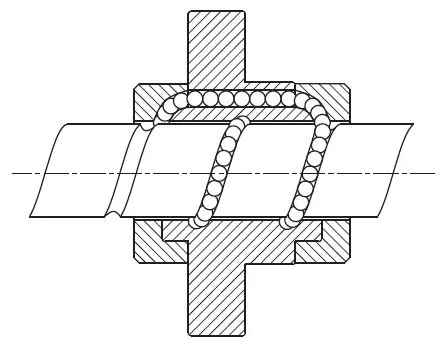

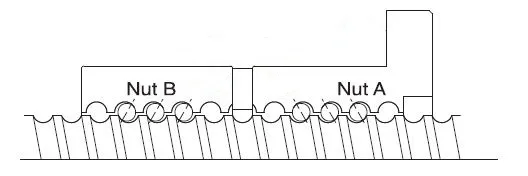

For systems requiring high preload amounts of around 6% to 10%, the most common method is the use of a double-nut system. This nut is found in applications where rigidity is very critical to its function and vibrations or shock loads are present. The double-nut is basically two single nuts against each other connected via a spacer or spring. While they do provide the most rigid of all the available nut-based solutions they are also the most challenging to mount. They also use up valuable travel length in smaller applications due to their larger size.

If backlash or slip is not a concern in your application, it is recommended to choose a ball screw with larger clearance (directly related to accuracy grade). This will keep the cost down and prevent overdesigning.

Leave a Comment

Your email address will not be published. Required fields are marked *