Should we prioritize ball screws over trapezoidal screws?

The difference between ball screws and the trapezoidal screw is getting smaller as technology advances. Solutions for many applications start to overlap and it's becoming more difficult for engineers to determine the best possible design for their mechanical construction. Special materials have given new life to the usefulness of trapezoidal screws as they are no longer used just for low-cost and low-precision applications. With higher load capacities and better positioning accuracy, they are now better than ever.

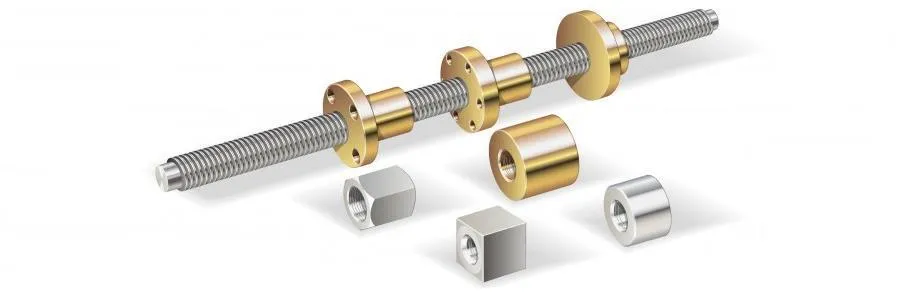

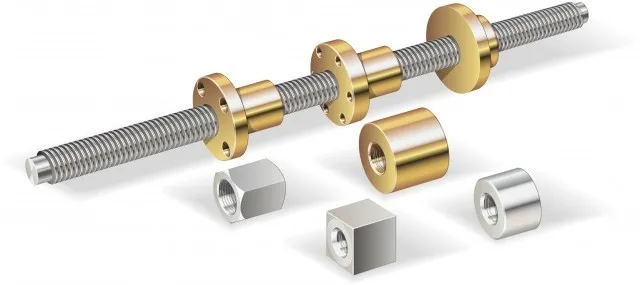

Trapezoidal screws

Trapezoidal screws or lead screws as they are alternatively known incorporate a traditional nut and a screw with no rolling mechanisms what so ever. They rely on the angle of thread and friction between the surface of the screw and nut to allow motion. The screw is usually made of steel, while the nut can be out of bronze or plastic.

Ball screws

Ball screws include a screw and a nut as well, but in the case of the ball screws, the nut houses recirculating small spherical objects aka balls to carry the necessary load. This design drastically reduces friction and provides a higher load carrying capacity and higher precision.

When to use ball screws and when to use trapezoidal screws?

Of course, there is no overall winner as there are still best-fit applications for each technology. In some instances, the mechanical requirements exceed the capabilities of lead screws and thus leave ball screws as the only choice. But the high initial cost makes a bad impression so alternatives are always welcome.

When it comes to heavy loads, accuracy requirements, maximum speed and efficiency the ball screw is way ahead in all accounts. Due to ball screws consisting out of rolling elements the assembly relies on point contacts to carry the necessary load. This allows for a higher efficiency compared to trapezoidal screws which rely on line contact. The difference in efficiency is staggering as ball screws can have an efficiency value above 90% while its counterparts aka trapezoidal screws have a merely 50% or an even lower value. Because of this trapezoidal screws are self-locking, which is necessary in some cases.

Another extra bonus for ball screws is that they can be preloaded, and usually are, to remove backlash during operations. This results in an increase in accuracy which cannot be achieved with regular trapezoidal screws.

So to answer an overdue question: yes, one should always prioritize ball screws over trapezoidal screws, but of course some exceptions can be made in certain applications.

Leave a Comment

Your email address will not be published. Required fields are marked *