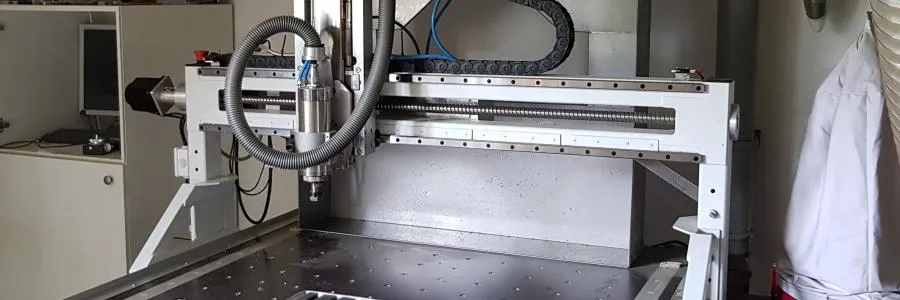

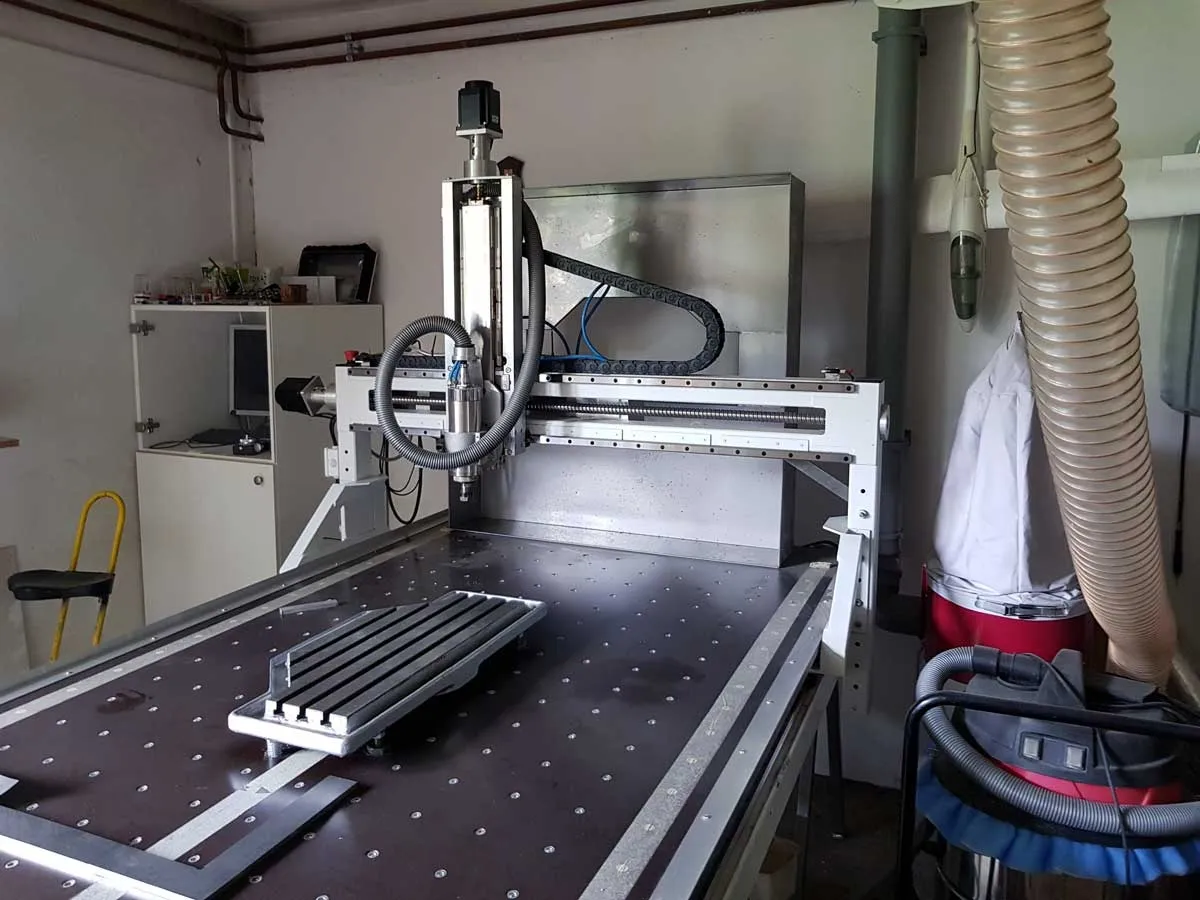

CNC mill 3x1,4x0,45 m

For milling the molds for the design of aircraft models, Issembled a CNC mill with a working surface of 3x1.4x0.45 m.

List of Tuli products used in the project

- ball screws and nuts of 25x10

Production

The basic framework is made from steel construction. For a longer longitudinal axis, I used two parallel ball screws and nuts of 25x10. I also used the same size of the threaded screw and nut for the other two axes. The longitudinal screws are fixed from both sides because of the length of more than 3 m and are slightly preloaded. I used radial axial bearings 7202 for the screw bearing. In addition, I have also made screw supports that are overridden by the moving axis during the processing and thus they retract. All the crews are connected via an electric motor through the GESM coupling. The TR 20 H linear guides are used as guides and TRH 20 VL H Z1 carriages are used for all three axes. A Water-cooled Screw Motor is installed on the vertical axis. I've used the CPS 033 Energy Chain for cable routing. The machine has been operating since 2015 without any problems. Also, the precision is very good especially when processing small pieces.

Leave a Comment

Your email address will not be published. Required fields are marked *