DIY laser paper cutter

The purpose of the project

Development of CNC cutting tool for various materials:

- Laser cutter

- Milling machines

- Plasma cutters

- Robotics

In our case, a laser cutter is designed for use in graphics and design. The bases come from various online presentations "DIY laser cutter"

Planed parameters of the system

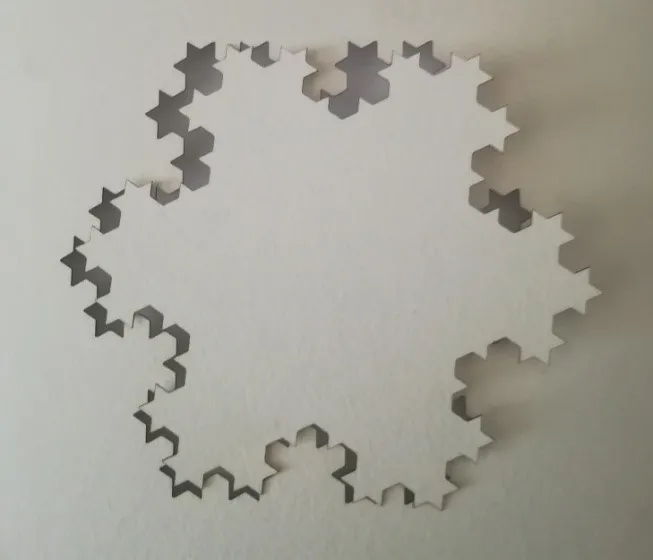

- Cutting paper up to a size A2 and a density of 300 g/m2 on a swivel table in the ZZ-axis up to the depth of 200 mm

- Cardboard cutting with a density of over 400 g/m2

- Plexiglas cutting

- Engraving on wood

- Use of graphics - in JPG, BMP, PNG format

- Use of graphic backgrounds in DXF format

- Use of vector graphics SVG

- G-Code programming format for controlling the cutter

The estimated final cutting system is a CO2 laser power of up to 60W. In the first step, a 2.5 W blue laser 445 nm is used for testing all mechanical, driving, electronic and software assemblies.

Mechanical, electronic and software assemblies

The following mechatronic components must be mastered in the development of a CNC machine:

- Mechanical assemblies, guides, drives,

- Stepper motors, servo motors,

- The motor drives electronic drivers,

- Control electronics,

- CNC software

- CAD/CAM software

- Graphics software

- The connection between the machine and development software tools

Leadshine Closed Loop system ES-D808 and a motor with an incremental encoder

Leadshine stepper motor microcontroller and NEMA 24 stepper motor

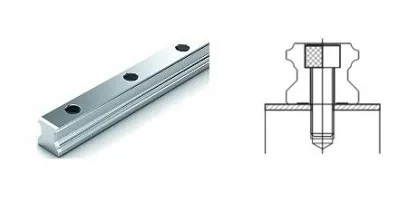

T5 toothed pulley and PU toothed belt

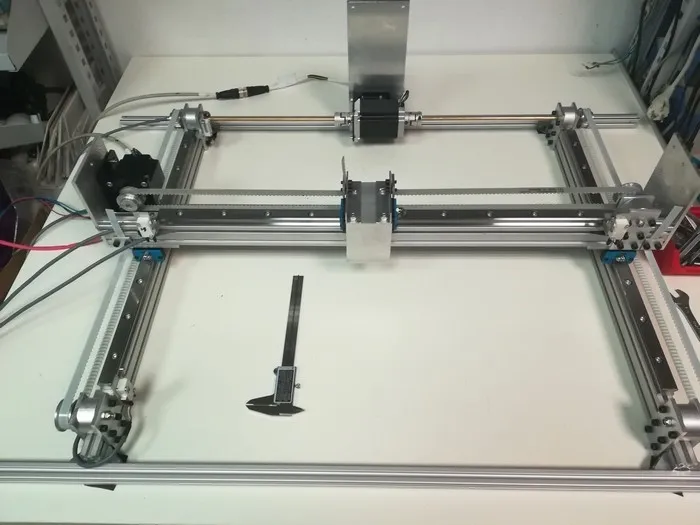

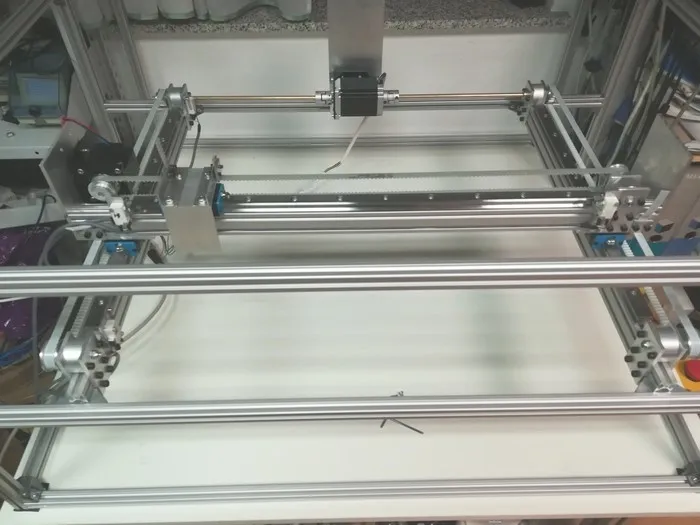

Guides and drives for X and Y axis construction

Course of development

The development took place step-by-step, which allowed a gradual control of all system elements:

– Testing the operation of the open-loop system with the stepper motor and the closed-loop system with a position encoder. For the cutter, the step-by-step drive with a micro-step controller (1600 steps per turn) is in the open-loop, and for more demanding drives we have already prepared a solution with a hybrid Closed Loop servo driver and motor.

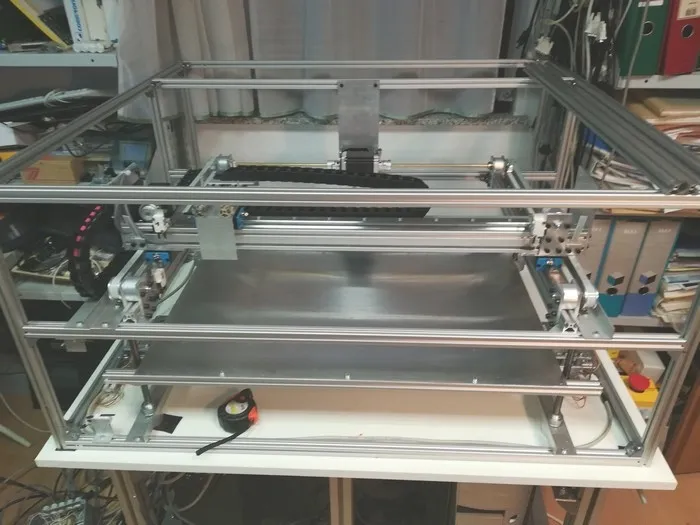

– The device includes X, Y, drives with NEMA 24 and Z drive with two NEMA 17 motors and a TR12x3 screw

– For movements in the X and Y directions, the TR5 toothed belt is used for the shifts in the Z direction, but the four vertical screws are driven by two stepper motors.

– All drivers are Leadshine DM556

– The guides are TULI TR20 with TRH20 carriages, fitted to ALU profiling 20x20mm and 20x40mm technical equipment.

– The mechanical construction consists of a chassis made of 45x45L ALU profiles, with a MACH3 program computer, and housing with power supplies, an LPT interface in the control signals, electronic drivers for stepper motors. An upgrade construction is made of 20x20mm ALU profiles with a built-in guide system and lifting table as well as with a prepared space for the CO2 laser tube. The accompanying systems for the laser system will be installed in the chassis.

Results

- The mechanical part works very well. There may be some simplifications in future projects.

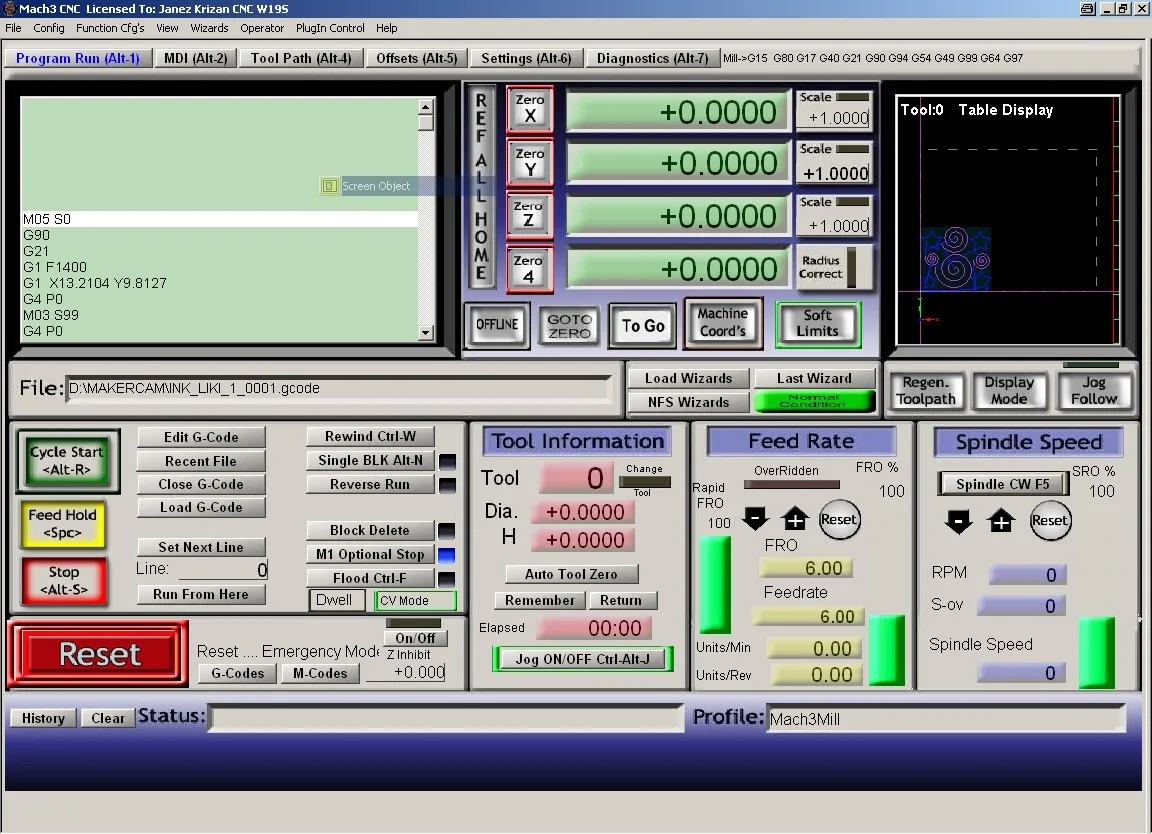

- The MACH3 control provides a universal G-Code application and is a verified and fairly cheap solution.

- For the laser system, PWM is used to activate and change the laser power even in the case of the MACH3 system.

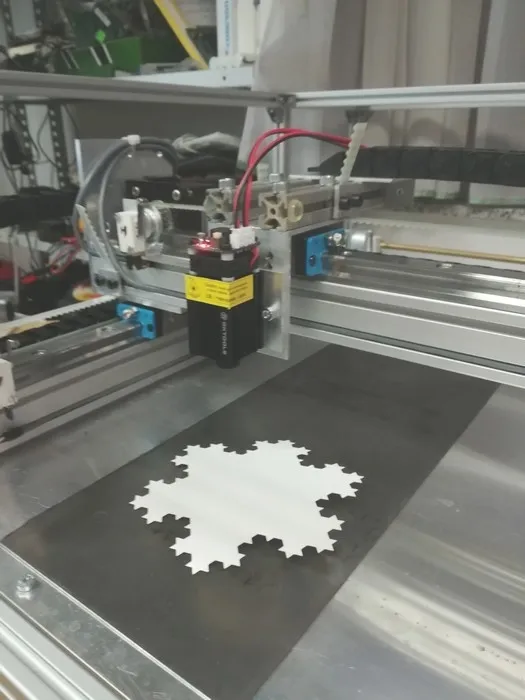

- The 445 nm laser has shown against our expectation good results for our application.

Continuation

In the next two months, the purchase of elements for the CO2 laser part will be carried out:

– 60W laser tube with power supply

– Cooling system

– A system of mirrors and lenses

- The body of the cutter with radiation protection and honeycomb on the table will be finished.

- Dust and smoke (that is produced by cutting and filtering) extraction system will be created.

- Based on experience, we can very quickly continue to build specific industrial systems.

- We master the drive control for small systems.

- We will try newer software and hardware systems such as SMOOTHIE-Board, special-purpose controllers, GRBL systems.

Construction with mounted guides for X and Y-axis

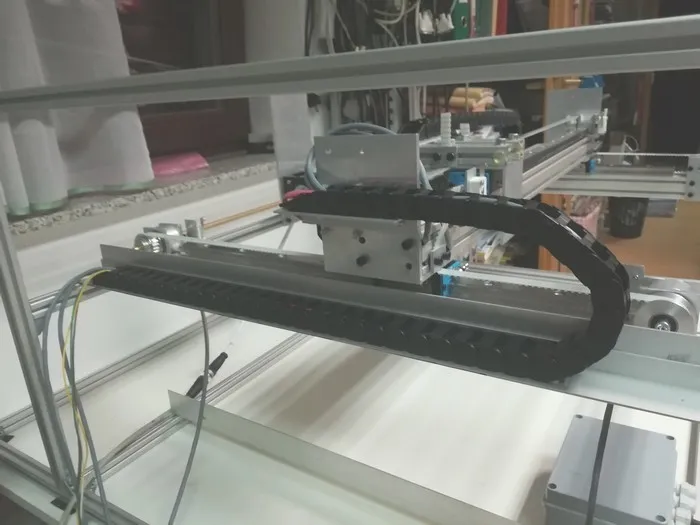

A cable channel

Cutting table with a displacement in the Z-axis

CNC control software for MACH3

Interface MACH3 LPT port to control the motors and switches

Laser 445 nm 2,5 W for cutter testing

Laser installation and cut-out paper

Leave a Comment

Your email address will not be published. Required fields are marked *