Linear bearings - LM vs LME type

Linear bearings are a key component of many machines where linear motion is required. Linear bearings enable precise and easy movement along the linear guide. This is extremely important in many industries such as mechanical engineering, automation, CNC machines, 3D printers, medical equipment, conveyor belts and many others.

There are several types of linear bearings, which differ according to their construction, shape and purpose of use. When choosing linear bearings, we must therefore understand the differences between individual types in order to avoid unnecessary problems in the operation of machines and devices. Among the most popular types of linear bearings are the LM and LME types of linear bearing bushings. In this article, we will explore their features and differences.

| Check LM and LME linear bearings in e-shop | Online shop |

LM and LME linear bearing bushings are basically very similar in construction, shape and appearance. They are simple, affordable and very effective. They are suitable for light loads where precise and fast linear movement is required.

In both cases, bearing balls are used as a rolling element between the bearing and the linear guide. The bearing housing is made of sheet steel and inside are balls that can have a plastic or metal cage. They can also be equipped with seals that protect the bearing from dust and dirt and extend its service life. Assembly and replacement of LM and LME bearings is quite simple, allowing for quick and easy installation and replacement.

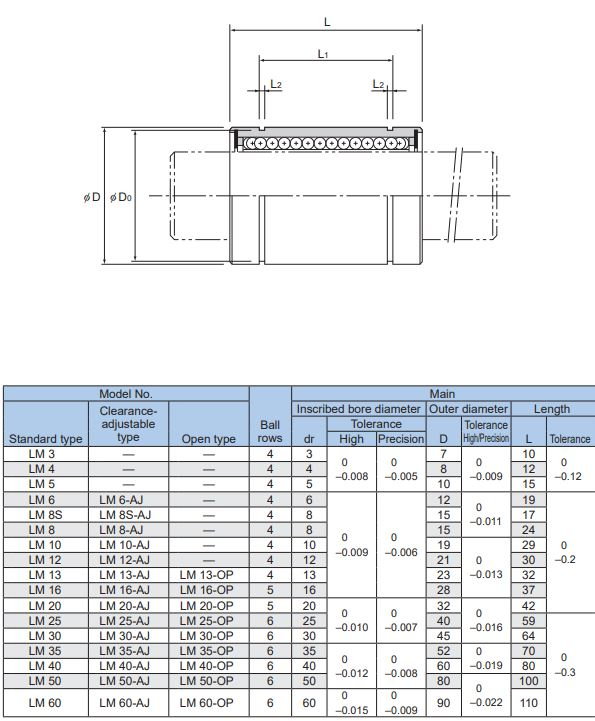

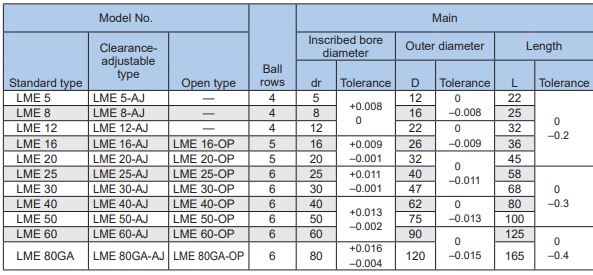

However, LM and LME bushings also have some differences that are good to know and understand. The differences stem from the fact that LM linear bearings are basically manufactured for Asian markets, while LME types are intended for European markets. The letter E in the label also indicates Europe. Differences thus occur in the dimensions of the outer diameter and length of the bearing, which typically deviate by a few mm. In most cases, LM types have a slightly smaller outer case and shorter length than LME types.

The main difference appears in the tolerance class of the inner diameter of the bearing. Namely, the LM type has this tolerance from 0 to minus, and the LME type from 0 to plus. For the example of an internal diameter of 16 mm, this means that the permissible dimensions for the LM type are from 16.00 to 15.991 mm, while the permissible dimensions for the LME type are from 16.00 to 16.009 mm. When using an LM and LME bearing on a linear guide with tolerance class h6, in the case of the LM bearing a transient fit occurs, while the LME bearing has a loose fit with the guide and thus a slightly larger clearance. In principle, greater clearance also means slightly smoother movement and greater tolerance for irregularities during assembly.

Therefore, LM and LME linear bearings cannot be directly replaced with each other without interfering with other parts of the structure. First of all, we must pay attention to frequent dimensional deviations. Special attention must also be paid to the different fits and clearances between the bearing and the linear guide in one case or another. When choosing, it is also important to consider the loads, speeds and required accuracy of movement in order to choose the right type of linear bearing for your needs.

Leave a Comment

Your email address will not be published. Required fields are marked *