Linear Guide Rails Selection – Where to start?

If you started to build a machine or a device where you also need linear movement, you quickly come across the question of which linear guide rails would be the most suitable for use. When examining the extremely wide range of guides on the market, where there are many different types of guides, sizes, precision, and different price ranges, the dilemma quickly arises as to which guide rails to choose.

Researching and comparing all possible options can be very time-consuming and complex. To help you with the first steps in choosing linear guides, we have therefore prepared some steps and instructions that can facilitate and speed up the selection process.

1.) Check what linear guide rails are used in similar machines

There is a very high probability that someone has already made a machine or device that is very similar to your example. Therefore, it makes a lot of sense to do at least a quick research as a first step and try to get information about the linear guides used in similar machines. The more well-known machine manufacturers are concerned, the more likely it is that their engineers have made detailed analyzes and calculations when choosing the guides and that they have chosen the most optimal guides, also from the point of view of appropriate precision and stiffness of the linear guides. Usually, such guides have also been tested many times in practice.

| Find linear guide rails in e-shop | Online shop |

2.) Assessment of the loads in your case

At the beginning, it is also necessary to make at least a rough assessment of the loads on the guide rails that will occur in your case. The largest or the most critical load usually occurs in the event of an emergency stop or a machine collision. In this case, a very rapid stop occurs, which causes enormous forces on the guides. The moment loads that arise in such a situation are usually the most critical. And that is why it makes sense to make an estimate of the load on the linear guides in such a case.

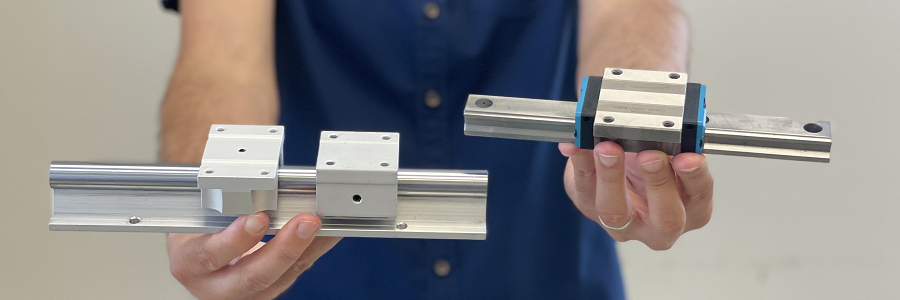

3.) Evaluation of the load capacity of linear guide rails

When you have managed to obtain information about the type of linear guides used in similar machines, it makes sense to check the load capacity of such guides and compare them with your loads. As for the load capacity of linear guides, the most critical part is usually the linear bearing, linear carriage, linear bushing... That is, the moving part of the linear guide assembly. And therefore it is necessary to check the load capacity of this part. Linear bearings and carriages typically have a dynamic load capacity factor C and a static load capacity factor C0 specified in the catalogs. These are the two factors that are used in the formulas for detailed calculations of the life of linear guides. For a first very rough estimate, we can take 10-20% of the value of the dynamic load capacity C, as the load capacity for cases of dynamic movement. If we have an extremely slow movement, we can directly take the entire value of C0 as a very rough estimate of the carrying capacity. The above estimate applies to cases of compressive and tensile loads on the guide and not to moment loads. Linear bearings and carriages tolerate torque loads significantly worse than compression and tension ones. Therefore, it makes the most sense to get rid of them with the correct placement of the guides (2x parallel guide + 4x linear bearing or carriage (2x on each guide)).

4.) Calculation of the lifetime of linear guides

With the help of the previous steps, we arrived at the basic selection of linear guide rails and linear blocks using very rough methods. For the final selection or confirmation of the selected guides and linear blocks, it is necessary to calculate the lifetime, which will show whether the selected guides will have the expected lifespan and are therefore suitable for use. In the calculation, other factors such as the type of load, location, speed, vibration, temperature, cleanliness of the working environment… are taken into account in addition to the data on the actual load. Detailed instructions and guidelines for the calculation are given in the manufacturers' catalogs. In our experience, the German linear guide rails manufacturers Bosch-Rexroth provide the best instructions for calculating in their catalogs. However, there are also many online configurators that can help you with the calculation and selection.

5.) Choice of manufacturer or brands of linear guides

Many linear guides are made according to standards or they are produced by different manufacturers with identical key dimensions and very similar characteristics and load capacities, which allows interchangeability between different guideway manufacturers. Of course, every time it is necessary to check and compare all key dimensions, load factors, and if the precision classes are also comparable. At this point, however, a warning applies that in the case of rail guides, the linear carriages and guides must be from the same manufacturer.

From here on, the matter of choice depends mainly on the quality/price ratio. Premium manufacturers such as Bosch-Rexroth, INA, Schneeberger, THK, NSK, HepcoMotion are famous for their high quality and reliability, and have prices accordingly. Very good choices in the middle class are TBI Motion and Hiwin, which have the best ratio between quality and price. Of course, low-priced ECONOMY designs are also available for cases where a favorable price is the main factor.

Leave a Comment

Your email address will not be published. Required fields are marked *