All About Miniature Linear Guides

Miniature linear guides, or miniature linear rail systems, are perfect for applications where space is limited, high precision is required, or weight is at a premium. They are small versions of standard linear guides and offer similar functionality but offer special features including:

Compact Size: As their primary feature, miniature linear guides are significantly smaller than standard guides, making them ideal for applications with space constraints, such as in medical devices, small-scale automation, and precision instruments. Often, miniature linear guides are used where headroom is at a premium and the low vertical profile of the miniature guides are attractive to the designer.

Lightweight: The small size and employment of lightweight materials make miniature linear guides ideal for applications where reducing the overall weight of the system is a priority, such as in aerospace applications, or sensitive imaging equipment.

Quiet Operation: Because miniature guides are used so often in laboratory settings, medical environments, and other sensitive applications these assemblies often are designed for low vibration and low radiated noise.

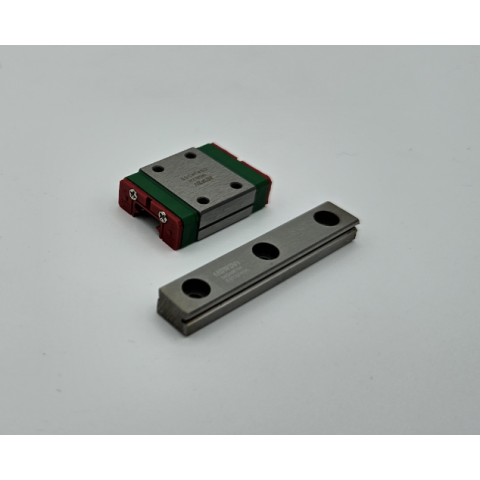

Like linear guides, the miniature versions share much of the same variety in rail length and load carrying capacity: to increase capacity, multiple parallel rails can be used, as can multiple blocks on a single rail. Miniature linear guide rails and blocks are typically made from stainless steel due to its anti-corrosion properties and dimensional stability, however, lightweight materials such as ceramic coated aluminum is also used.

Figure 1 Miniature linear guides

Miniature Guides vs Miniature Slides

The term “miniature guide” usually refers to assemblies of rails and blocks that have ball bearings between them. Friction in these assemblies is reduced to a minimum by the point contact of the balls on the grooves in the rail and blocks. These are precision assemblies, and unless a cage is included in the block system, the blocks often can’t be easily removed from the rail without releasing the balls. Some applications for low friction linear motion do not justify this high precision and large part count. For these applications, a miniature slide might be a more economical option.

Made by several companies including PBC Linear, linear slides are the plain bearing version of a linear guide, using PTFE (Frelon is a common trade name) and other low-friction materials as the interface between the stationary and moving part instead of ball bearings. PTFE materials such as Frelon have the other nice property of being self-lubricating as some of the of the soft PTFE is transferred from the block to the rail during operation. Slides can typically support four to eight times the load of a comparable guide that uses ball bearings due to the much larger bearing surface in the slide. While slides are also much less expensive than guides due to the simplicity of the slide, the slide of course includes more friction than a guide. Slides are also not as precise as ball bearing guides since the ball bearing guides have adjustable preload to take out the clearance between the balls and the rail.

Figure 2 Miniature Slides

Design Considerations for Miniature Linear Guides

Linear guides allow for constrained, predicable motion of a load (a subassembly or payload) along one axis. Designers who use these assemblies address various considerations when specifying linear guides.

Versatility: Linear guides can be customized in various ways, including different lengths, widths, and configurations, to suit specific application and load requirements. Since joining rail segments can be problematic, finding a rail system with customizable lengths to maintain a joint-free rail can be important. Most blocks are not meant to be removed from the rails often: if field removal of the blocks from the rails is an important consideration, then a linear slide or a caged guide might be a better option if the higher friction and lower precision can be tolerated.

Corrosion Resistance: Some applications demand a linear guide to operate in corrosive environments such as marine environments or industrial processes that use corrosive chemicals. In other cases, such as cleanroom environments, no oil or grease can be tolerated so the bearings must be able to operate with long lifespan without these traditional lubricants. When they can be specified, miniature slides have a longer lifespan in corrosive environments than ball bearing guides due to their simplicity.

Easy Installation and Maintenance: Miniature linear guides are generally designed for ease of installation and maintenance, with features like pre-drilled mounting holes and some boast the ability to be easily disassembled for cleaning or replacement. For installation of the rail to the machine assembly, a machined shoulder to register the rail against is an important design feature when accurate alignment is important: most rails specify a registration edge for this purpose. Blocks often include blind tapped holes on the top face for mounting the moving assembly.

Some blocks have wipers that can be installed on the front and rear face of the block to keep the ball bearings as clean as possible and reduce maintenance requirements. Also included on various models of blocks is a lubrication port: the designer will want to make sure the assembly is mounted to allow access to this port for maintenance.

High Precision and Accuracy: Miniature linear guides provide precise and accurate linear motion, which is essential in applications like semiconductor manufacturing, laboratory automation, and other high-precision tasks. There are several techniques that manufacturers use to improve the accuracy of linear guides, including a user-adjustable feature on the block to preload the bearing. Increasing the preload uniformly squeezes the balls in the block’s raceway against the rail to decrease any clearance that the payload creates.

Low Friction and Smooth Motion: Miniature linear guides are designed with various clever ball return techniques that fit in their small form-factor to minimize friction and ensure smooth motion of the block along the rail. Avoiding vibrations created by the block’s motion on the rail is an important design goal, particularly important in applications where control and precision are paramount such as imaging or precise cutting.

High Load Capacity Relative to Size: Despite their small size, miniature linear guides can support relatively high loads though the inclusion of ball bearings as large in diameter as possible. If ultra-low friction is not required, then a designer would be wise to consider a linear slide, which can typically carry four to eight times the load of a ball bearing guide while still maintaining a low enough profile to be considered a miniature linear bearing.

It is important to know the moment that will be applied to the bearing assembly by offset loads. Some miniature guide rails, like those from THK, have two raceways incorporated into the block body that can receive loads in all directions as well as sustain an applied moment using a single rail.

WON miniature linear guides also provide exceptional load capacity in a very small space with a four-point contact ball recirculation system that features 45 degree loading angles to accommodate loading from many directions.

Applications for Miniature Linear Guides

Miniature linear guides are favorites for designers when faced with a need for low profile, lightweight, or very precise linear motion. Some of the applications where these find use are in:

- medical, scientific, and industrial imaging and photonic systems where low vibration and smooth, repeatable motion is important for focusing, alignment of lasers, and positioning;

- industrial automation end-effectors where lightweight precise positioning is needed;

- 3D printing and CNC machining for precise positioning of parts and tool heads in small volumes;

- metrology and inspection applications use miniature linear guides for their high precision measuring tasks;

- small-scale packaging and labeling machinery relies on miniature linear guides where precise positioning is important; and

Leave a Comment

Your email address will not be published. Required fields are marked *