SHAFT SELECTION FOR LINEAR GUIDE BEARINGS

For a mechanical design based on linear technology, the shaft is the main guide of the bearing and therefore has a significant impact on the life expectancy of the linear bearing system.

Plain and recirculating linear bearings can be combined with shafts made from different materials to meet the demands of the application or environmental requirements. It is common to pair off a shaft made from stainless steel or high-grade carbon steel with a recirculating ball bearing. The same shafts (from carbon, stainless steel or aluminum) can also be used together with plain bearings. For harsh environments or extreme conditions, special coatings and platings can be used to endure abrasive or corrosive particles.

Before making a choice which shaft material and coating to use, two factors affect linear guide bearing work-life expectancy. The first is is the surface finish of the shaft, and the second is surface hardness.

SURFACE FINISH OF THE SHAFT

Also known as surface topography, it measures the deviations of a surface from the perfectly flat ideal which is a true plane. For recirculating bearings, it is best to have a well-polished surface. A well-polished surface will provide more contact area between the bearing and the shaft. However, a rough shaft surface will provide less surface contact area due to a greater number of peaks and valleys. A standard surface finish for shafts paired off with a recirculating ball bearing is around 0,15 μm to 0.3 μm Ra.

On the other hand, a plain linear bearing will suffer in work-life expectancy from a smoother shaft surface. In some instances, it can lead to additional wear due to the reliance of plain bearing on its self-lubricating characteristics. Plain bearings benefit from a larger number of peaks on the surface which help to transfer tiny chunks of bearing material to the shaft. This material fills in the crevices on the surface and then serves as some sort of lubricant as the bearing travels along the shaft. Without self-lubrication, plain bearings would have a lower PV rating due to higher friction between the bearing and the shaft.

The same applies to plain bearings made from bronze, which also require outside lubrication. Slight roughness of the shaft helps prevent bearing to shaft contact by retaining lubricant in its micro-crevices. That being said, too much roughness can have the opposite effect and cause an increase in wear and tear. The recommended surface finish values depend on the bearing material, but generally, it varies between 0,2 μm to 0,4 μm Ra.

SURFACE HARDNESS OF THE SHAFT

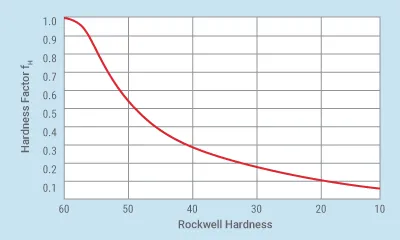

Recirculating linear bearing balls have a high impact on shaft wear due to point loading. Since heavy loads are distributed on a small surface, the shaft will need to be made out of a material with a high surface hardness to minimize its effects. Because of its importance, a shaft hardness factor is often included in max load and life expectancy calculations for recirculating ball bearings.

Standard recommendations for round shaft surface hardness is 60 HRC (Rockwell Hardness), for which the value of the shaft hardness factor is 1.0 (no drop in life expectancy nor an increase). For shaft HRC values under 60, there can be a significant reduction of the life expectancy of the entire bearing assembly. Do keep in mind that most stainless steels have an HRC value around 54, meaning designs which will use stainless steel shafts will have a reduced life expectancy if all other operating parameters stay the same.

For the plain bearings, surface shaft hardness is not as important as it is for recirculating linear bearings. Still, it does indeed play a role. Because plain linear bearings usually don't include any protection from dust or debris, contaminants can get stuck between the shaft and the plain bearing. In cases where the shaft (or plain bearing) are made from a soft material, the contaminants can embed themselves on the surface of the shaft (or plain bearing). This is, of course, unwelcome since it will increase wear and reduce life expectancy. As a final note, for plain bearing made from bronze, the shaft material must be of a different kind and must have a greater surface hardness than that of the linear plain bearing material.

Leave a Comment

Your email address will not be published. Required fields are marked *