The do's and don'ts of linear rail alignment

The easy way out is to design a linear guide system based on ball bushings, which can tolerate imprecise mounting and other misalignments. Sadly, this is not the case with profiled rails that require accurate mounting and alignment to ensure even load distribution among the recirculating balls. This is why profiled rails can only be used in applications that have tight tolerances.

Of course, this makes profiled rails more costly and time-consuming but their usage is justified for applications where regular bushings cannot bear the high load of the applications in question or when high accuracy and repeatability is of the utmost importance. So what do we need to pay attention to when installing linear rail guides?

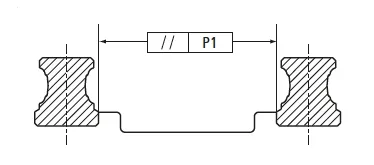

Rail Parallelism

The two-rail and four-rail designs are the most common linear rail guide installations. Regardless of the number of carriages, two rails are used in parallel. Some unnecessary load can result if the carriages are not mounted within the manufacturer’s specified parallelism tolerance. The most precise method for securing the rails would be by using a machined reference edge for each rail. The least precise method of mounting would be using a straight edge on one rail and then aligning the other rails via a connecting plate.

It is crucial to note that if the rails are not mounted against a reference, the permitted side force may be reduced. With no lateral retention, the rail mounting screws become the limiting factor for permitted side load.

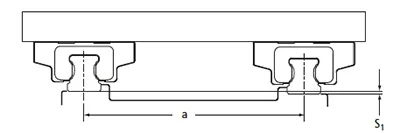

Offset between rails

When two rails are used in parallel they should also adhere to the maximum permitted offset in the vertical. If the permitted offset is overstepped it will result in an introduction of a roll moment which can drastically reduce bearing life expectancy. The maximum permittable vertical offset is often specified as a function of the distance between the rails and the preload of the carriages. The higher the preload, the smaller the vertical offset should be. Another factor that should be taken into account before calculating the vertical offset is the height tolerance of the carriages. If the height tolerance causes a higher offset than is permitted, other carriages with either higher accuracy or lower preload should be used.

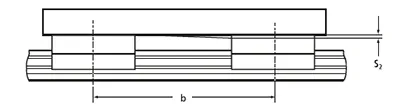

Vertical offset between carriages

The vertical offset between carriages becomes an important factor when multiple carriages are used on the same rail, such as in a four-rail design. In this case, the permitted vertical offset is a function of both the length of the carriages and the distance between the two carriages.

Just like with the vertical offset between rails the vertical offset between carriages also takes into account the height difference. If the vertical offset is higher than the permitted offset, then a higher accuracy version, or shorter carriages, should be used.

Proper mounting involves many factors; some of them aren't even related to the elements in use, such as the preparation of a good foundation, accuracy of reference edges and even the procedure for tightening the mounting screws have an influence. Non-demanding applications can often have acceptable performance with less-egregious mounting methods. But for the most demanding and highly accurate systems, one must follow the manufacturer's specifications to the letter as to ensure the highest accuracy possible and avoid reducing the life expectancy of the installation in question.

Leave a Comment

Your email address will not be published. Required fields are marked *