How to join aluminium profiles

Aluminium profiles are an engineer's grown-up version of Legos. The best way to describe these profiles would be as cheap, light and simple. In order to join two or more profiles, one needs to acquire the necessary joining elements. These components provide the mechanical bond that holds the aluminium profiles securely together.

| Find joining elements in our e-shop | Online shop |

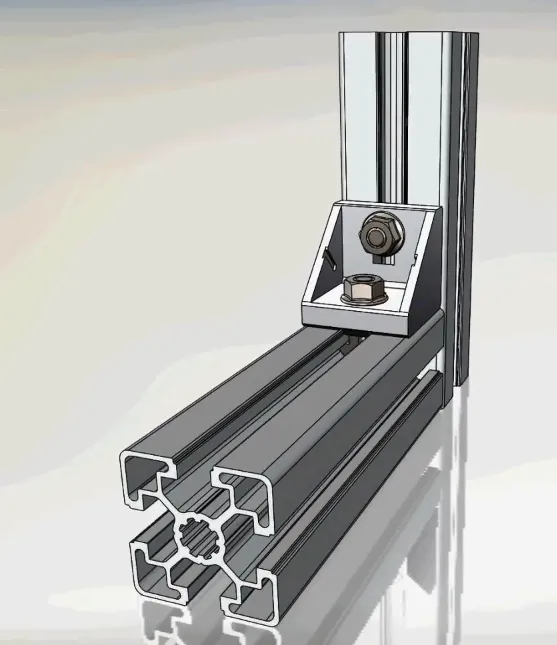

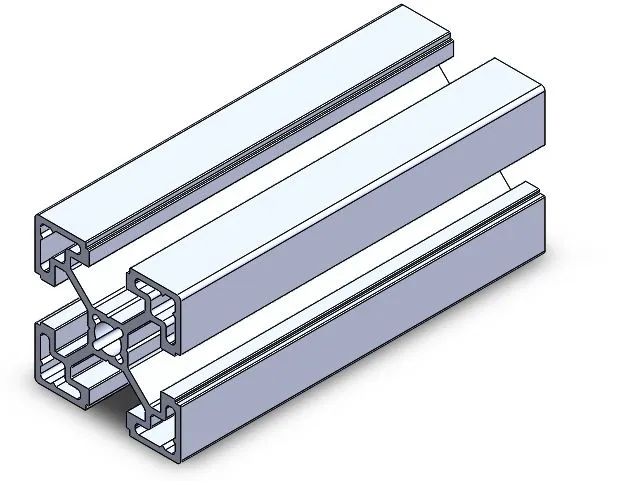

Picture 1: 40x40 aluminium profile.

Our online shop provides a wide variety of aluminum joining elements. Before you decide on a particular product, it is always best to compare different types of joining elements, and look at their strengths, and weaknesses and assemble specifics. To help you, we have compiled a list of 6 top joining elements.

Brackets

The most basic ones are brackets. Brackets are meant for 90-degree connections. Attaching a bracket is simple, it only requires a couple of screws and nuts and does not require additional machining of profiles.

To prepare the joint with the brackets, we need two aluminium profiles precisely cut at an angle of 90°. It makes sense to previously install a screw and a nut slightly attached to it in the bracket.

Then place the profiles on top of each other at an angle of 90° and place the bracket at the place of the joint so that the tabs on the back of the bracket sit in the groove of the profile.

If the positioning of the profiles is such that the tabs are in the way, simply break them off with a screwdriver.

The screw and nut are rotated accordingly so that the hammerhead sits inside the profile. Then tighten the screw and nut. We must make sure that the hammer head remains in the correct position inside the groove.

For the aluminium profile 30x30, the U8 hammer nuts are used together with the angle head screw.

For aluminium profiles 40x40 and larger, U10 hammer-head screws together with flanged nuts are used.

The main advantages of connecting profiles with external brackets are flexibility and adaptability, as they can be easily placed anywhere or moved to another location. The main disadvantage, on the other hand, is the aesthetic appearance and the required space.

An example of attaching two aluminium profiles can be seen in the picture below. Brackets are available for the following aluminium profile sizes: 30x30, 30x60, 40x40, 40x80, 45x45, 45x90, 60x60, 80x80 and 90x90.

Picture 2: Bracket for 90-degree connections.

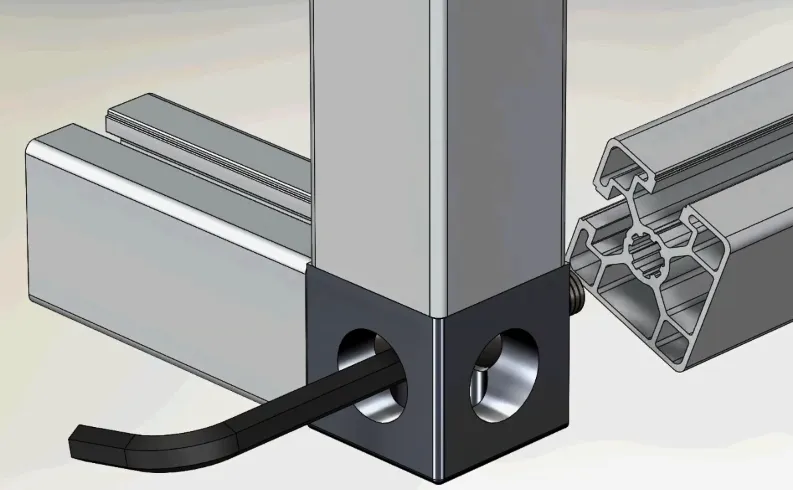

Corner connector cubes

A more elegant solution would be the use of corner connector cubes. With no protruding features, they are indeed pleasant on the eyes. Unfortunately, the downside is their higher price and that cube corner connectors are limited to only a few aluminium profile combinations: 30x30, 40x40 and 45x45. It is also important to note that before the assembly, it is necessary to form a thread inside the profile via a thread forming tap.

Picture 3: Corner connector cube.

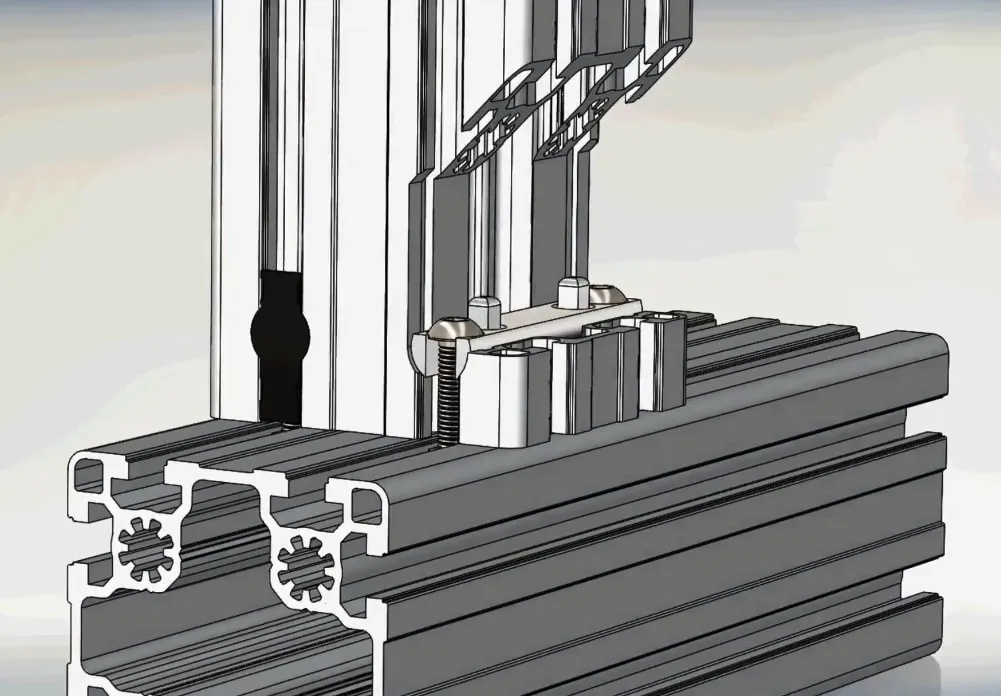

Connector sets

For a minimalistic approach, we offer a wide variety of connector sets. These are the best for unorthodox aluminium profile connections. The connections they form are strong but require some work to be done pre-assembly, from drilling holes in the profile for the inserts to forming threads for the necessary screws. Below, you can see more examples of joining element assembly for bolt connectors, connector sets, screw fitting, and profile connectors.

Bolt connectors are used for connecting two bolts in order to form a stronger mechanical bond. Its assembly requires a hole to be drilled throughout the profile.

Picture 4: Bolt connector set for aluminum profiles.

Milling connectors are made for making 90-degree or 0-degree profile connections. Just like the bolt connectors, they form a strong connection and they require a hole to be drilled.

Picture 5: 90-degree milling connector set.

Frontal connector sets

The most basic joining elements are frontal connector sets. They are ideal for less demanding applications and are used very often. They can withstand loads of 800-1000 N and moment loads 40 Nm. Frontal connector sets are available in two dimensions. The first one is for aluminium profiles with a slot 8 mm (size 30x30), and the second one is for aluminium profiles with a slot size 10 mm (size 40x40 and higher). Their assembly requires drilling a hole through one profile and forming a thread within another one.

The main advantage is that such a joint is hidden and does not require additional space. It also provides good rigidity and vibration resistance. The disadvantage is the required additional machining of the profile, which also makes it impossible to move such a joint.

Picture 6: Frontal connector set.

Linear joint connectors

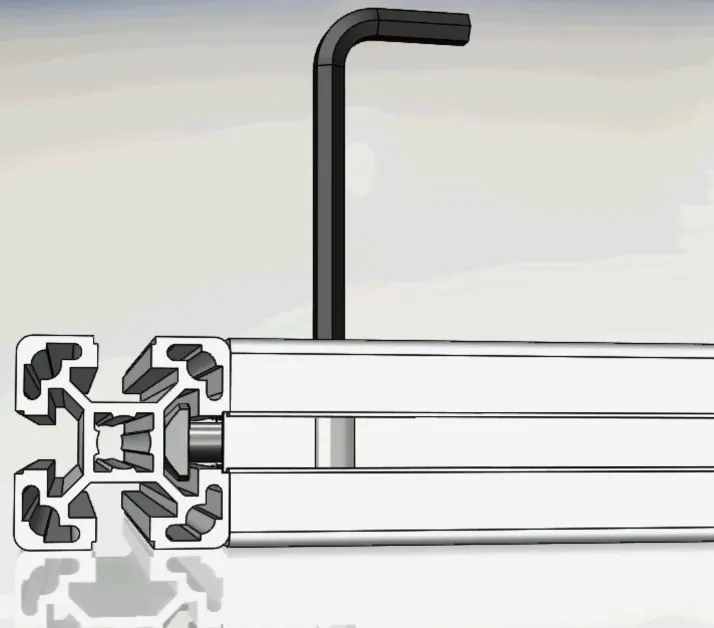

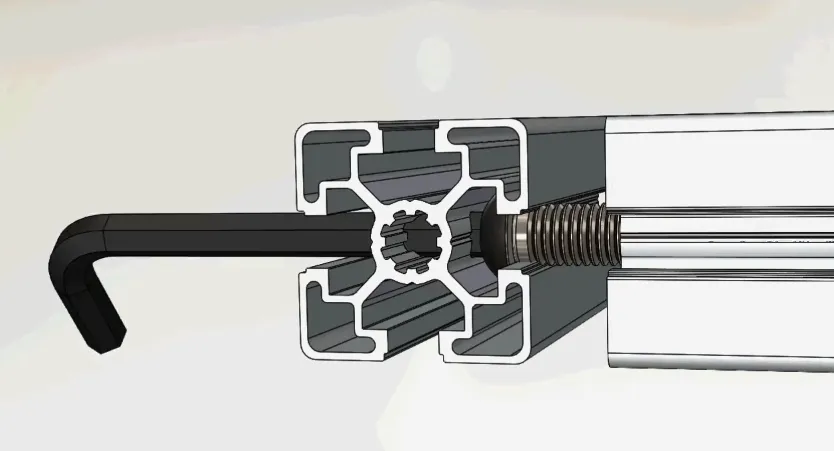

When there is a need for long profiles, but the logistical cost of transporting them is high, it makes more sense to cut them up into smaller pieces and then use linear connectors to assemble them. Linear joint connector is basically T-shaped nut with a long length. T shape is designed to fit in an aluminium profile slot. Before using this solution, you must double-check the load capacities of the linear connector joint. From a stiffness point of view, it is always better to use an aluminium profile from one part.

Picture 7: Linear connectors for longer aluminium profiles.

The ultimate comparison of joining elements for aluminium profiles

When constructing a system from aluminium profiles, one should take into account all the costs, not just the basic components. For instance, the cost of the necessary tools for assembly and time consumption also play an important role. Let this cross-reference chart help you in choosing the best possible solution for your aluminium profile assembly.

|

|

Milling Connector |

Brackets |

Inside Angle |

Bolt Connector |

Frontal connector set |

|

Flexibility of Usage |

5 |

5 |

2 |

2 |

3 |

|

Adjustability |

5 |

5 |

3 |

1 |

1 |

|

Frame Stiffness |

4 |

4 |

2 |

5 |

5 |

|

Vibration Resistance |

4 |

2 |

1 |

5 |

5 |

|

Space Requirement |

5 |

2 |

5 |

4 |

5 |

|

Assembly Time |

5 |

5 |

4 |

1 |

4 |

|

Cost-Effectiveness |

4 |

5 |

4 |

2 |

4 |

|

Aesthetic Finish |

5 |

1 |

5 |

5 |

5 |

5 = Highest/Best, 1 = Lowest/Worst

Truly, the application for aluminium profile systems is only limited by our imagination, pockets and time. For more information about aluminium profile systems feels free to browse our online shop or our assortment of catalogues.

Leave a Comment

Your email address will not be published. Required fields are marked *