FAG Bearings

About FAG

FAG (Fischers Aktien-Gesellschaft), a renowned German manufacturer, has been at the forefront of bearing innovation since its inception. With a commitment to precision engineering and cutting-edge technology, FAG has earned its reputation as a reliable and trusted producer of bearings.

Currently part of the Schaeffler Group, Germany’s fourth most innovative company according to the DPMA (German Patent and Trademark Office), makes FAG a trusted manufacturer, and innovation is guaranteed.

History of FAG Bearings

FAG bearings company was born when German inventor Friedrich Fischer created the ball grinding mill in 1883 and founded the company. This was a machine that allows steel balls to be ground to a perfect sphere.

When the company started operations, it did so in the world's first rolling bearing production plant. Altogether, this gave Mr. Fischer the title of “the father of the modern ball bearing” and FAG the recognition as the pioneering company in rolling bearing technology.

In 2001, FAG was taken by the Schaeffler Group, thus becoming an essential brand for the group’s presence in the aerospace, automotive and industrial markets.

Where FAG Bearings are Made

FAG bearings were first made in a plant near the train station in Schweinfurt, Mr. Fischer’s hometown. However, since becoming a brand of the Schaeffler Group, FAG bearings are made in different locations around the world. Locations include Europe, Asia, Brazil, USA and Canada.

FAG bearings are meticulously crafted in state-of-the-art manufacturing plants, adhering to stringent quality standards.

Types of FAG Bearings

With applications in the aerospace, automotive, and industrial sectors, FAG bearings have been developed in different types to cover every need. Here is a list of some bearings fabricated by FAG:

- Double row angular contact ball bearing

- Self-aligning ball bearing

- Spherical roller bearing, spherical roller thrust bearing

- Tapered roller bearing

- Double row deep groove ball bearing

- Axial deep groove ball bearing

- Single row deep groove ball bearing

- Single row angular contact ball bearing

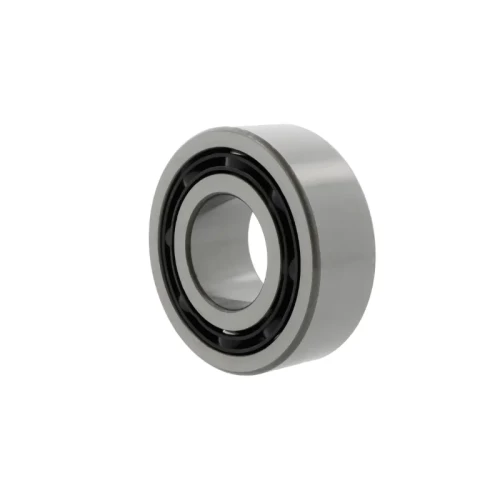

Figure 1 FAG bearings

FAG Ball Bearings

We must highlight FAG’s flagship product, ball bearings. These bearings bring to your machinery smooth operation and unmatched precision.

These bearings are engineered for optimal performance, ensuring longevity and efficiency in every rotation.

FAG ball bearings come in a wide variety of types, designs, series, sizes, variants and materials. Options include: deep groove ball bearing, angular contact ball bearing, self-aligning ball bearing, super precision ball bearing, among others.

FAG Ball Bearings Features

1. Precision Engineering

Experience unparalleled precision with FAG ball bearings. Crafted with meticulous attention to detail, these bearings ensure consistent and accurate performance, meeting the highest industry standards.

2. Enhanced Durability

Built to withstand the rigors of demanding applications, FAG ball bearings are engineered with durability in mind. Whether facing heavy loads or high-speed rotations, these bearings deliver reliable performance over the long haul.

3. Advanced Material Selection

FAG ball bearings are crafted from high-quality materials, chosen for their strength, resilience, and resistance to wear. This ensures optimal functionality even in challenging environments, providing you with a reliable solution for your machinery.

4. Low Friction Design

Benefit from the low-friction design of FAG ball bearings, reducing energy consumption and heat generation. This feature not only enhances efficiency but also contributes to the longevity of your machinery.

5. Sealed for Protection

Protect your machinery from contaminants and extend bearing life with the sealed design of FAG ball bearings. This innovative feature prevents dust, dirt, and other external elements from compromising the performance of your bearings.

6. Quiet Operation

Enjoy a smooth and quiet operation with FAG ball bearings. The precision manufacturing and advanced design elements contribute to a silent performance, creating a more comfortable working environment for your machinery.

7. Wide Range of Sizes and Configurations

Find the perfect fit for your application with our extensive range of ball bearing sizes and configurations. Whether you need miniature bearings for delicate machinery or larger bearings for heavy-duty applications, Tuli Shop has the solution.

8. Application Versatility

Adaptability is key, and FAG ball bearings are designed to excel in various applications. From automotive to industrial settings, these bearings offer the versatility needed to meet the diverse needs of your machinery.

Figure 2 Bearings

How to Select the Perfect FAG Bearings for Your Needs

Choosing the right FAG bearings is a critical decision that directly impacts the performance and longevity of your machinery. At Tuli, we understand the importance of finding the perfect fit for your specific requirements.

Here's a step-by-step guide to help you make an informed decision:

1. Identify Your Application Needs

Begin by understanding the specific demands of your application. Consider factors such as load capacity, speed requirements, and environmental conditions. This initial assessment will guide you towards bearings that are tailor-made for your machinery.

2. Determine Bearing Type

FAG offers a diverse range of bearing types, including ball bearings, roller bearings, and specialty bearings. Evaluate the characteristics of each type and choose the one that aligns with your application's demands. Whether it's precision ball bearings or robust roller bearings, our catalogue has a solution for you.

3. Consider Load and Speed Ratings

Take into account the expected loads and operating speeds your machinery will encounter. FAG provides load and speed ratings for each bearing, helping you select a bearing that can handle the specific demands of your application without compromising performance.

4. Understand Mounting and Fitment Requirements

Different applications may have varying mounting and fitment specifications. Ensure that the chosen FAG bearings match these requirements seamlessly. Proper installation is key to maximizing the performance and lifespan of your bearings.

5. Temperature and Environmental Factors

Assess the operating environment for your machinery. FAG bearings are designed to perform in a wide range of temperatures and conditions. Choose bearings that can withstand the environmental challenges your machinery may face, ensuring longevity and reliability.

6. Sealing and Lubrication

Consider the level of protection your machinery requires. FAG bearings come with different sealing options to prevent contamination. Additionally, choose the right lubrication to optimize performance and reduce maintenance needs.

7. Consult with Experts

Still unsure about the best bearing choice for your application? Our team of experts is here to assist you. Feel free to reach out for personalized guidance and recommendations based on your specific requirements.

Your Journey Starts Here

Embark on a journey of reliability and excellence with Tuli Shop's collection of FAG bearings. Explore our catalogue, find the perfect bearing for your needs, and experience the difference that precision engineering can make.

Trust Tuli Shop for all your bearing needs.

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

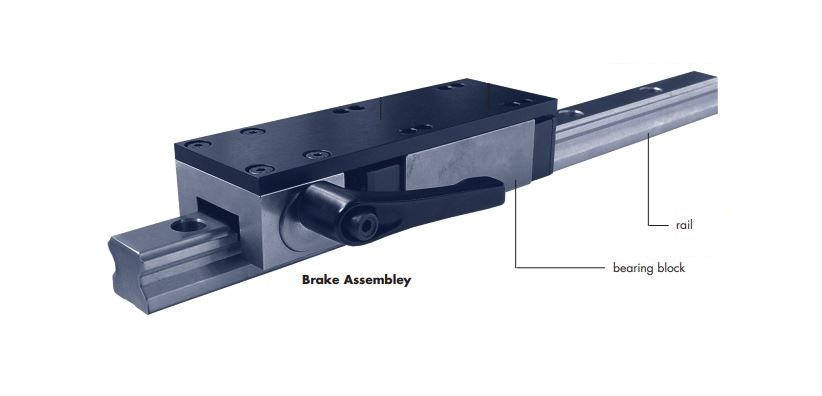

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...