TIMKEN Bearings

About TIMKEN

TIMKEN, a global leader in bearing technology, has been revolutionizing industries for over a century. With a legacy built on innovation, reliability, and customer satisfaction, TIMKEN continues to set the standard for excellence in motion.

Thanks to their impressive R&D capabilities and engineering expertise, they deliver tailor-made products with consistent and reliable performance that make them the top choice for many applications.

The company received the recognition among America’s Most Innovative Companies by Fortune and Statista in 2023. This supports their innovative nature.

Moreover, they have received other recognitions in different areas, including environmental sustainability and ethics.

History of TIMKEN Bearings

The rich history of TIMKEN bearings, from its humble beginnings to becoming a powerhouse in the industry, started more than 120 years ago when heavy freight wagons had a difficult time making sharp turns.

Henry Timken, a carriage maker in St. Louis, Missouri, was decided to solve the problem. To do so, he designed a tapered roller bearing that could handle both radial (weight) and thrust (cornering force) loads.

The results from applying his new design were astonishing, and customers were happy with all the benefits received. Mister Timken immediately understood that the tapered roller bearing could improve product performance in many other applications as well.

In 1899, Henry and his sons, H.H. and William, founded The Timken Roller Bearing and Axle Company, the foundation for what we know as TIMKEN today.

Figure 1 Timken bearings

Where TIMKEN Bearings are Made

Starting out in St. Louis, and then moving into Canton, Ohio, now TIMKEN manufactures bearings in state-of-the-art plants across 33 countries around the world.

These locations include:

- USA

- Mexico

- France

- Romania

- Italy

- Poland

- United Kingdom

- India

While located in various regions worldwide, TIMKEN bearings production plants uphold the highest standards of quality and precision, ensuring that every TIMKEN bearing meets stringent criteria.

Types of TIMKEN Bearings

Delivering strong performance, consistently and reliably to the automotive, aerospace and other industrial sectors, Timken develops different types of engineered bearings that include:

- Timken ball bearings

- Timken cylindrical bearings

- Timken tapered roller bearings

- Timken spherical roller bearings

- Timken adapt roller bearings

- Timken plain bearings

- Timken thrust bearings

- Timken precision bearings

Figure 2 Timken tapered roller bearing

TIMKEN Bearings Features

These are the exceptional features that set TIMKEN bearings apart from the rest:

1. Precision Engineering

Each TIMKEN bearing is crafted with precision and attention to detail, ensuring consistent performance and reliability while meeting the highest industry standards. High precision tolerances are guarantee all these is achieved.

2. Increased Durability

Built to withstand the toughest conditions, TIMKEN bearings are engineered for longevity, reducing downtime and maintenance costs.

3. Innovative Design

Benefit from TIMKEN's innovative design solutions, optimized for efficiency, performance, and ease of installation.

4. Proprietary Internal Geometries

TIMKEN bearings feature proprietary internal geometries that optimize load distribution, minimize friction, and enhance overall performance. These advanced geometries are meticulously engineered to maximize efficiency and durability, ensuring smooth operation and extended bearing life.

5. Advanced Material Selection

TIMKEN bearings are constructed from high-quality materials chosen for their strength, resilience, and ability to withstand harsh operating conditions. This ensures optimal performance and reliability in even the most demanding applications.

6. Sealed for Protection

Keep contaminants at bay with TIMKEN's advanced sealing technology, protecting your machinery and extending bearing life.

7. Wide Range of Sizes and Configurations

From miniature bearings to large-scale solutions, TIMKEN offers a comprehensive range of sizes and configurations to accommodate a diverse array of machinery and applications. Whether you need a standard size or a custom solution, Tuli has you covered.

8. Application Versatility

Whether it's automotive, aerospace, or industrial applications, TIMKEN bearings offer versatility and adaptability to meet the diverse needs of our customers.

How to Select TIMKEN Bearings - Your Guide to Making the Right Choice

Choosing the perfect TIMKEN bearing for your application is crucial. At Tuli, we understand the criticality of finding the perfect fit for your specific needs. Here's how to make a smart and informed decision:

1. Assess Your Application Needs

Identify the specific requirements and operating conditions of your machinery. Analyze aspects such as load capacity, speed requirements, and environmental conditions. With this analysis you will start discarding the options that do not meet your needs and keep the ones that might be the right choice.

2. Understand Bearing Types

Familiarize yourself with the different types of TIMKEN bearings available and their respective advantages. Assess the features of each type and select the one that meets your application's requirements. Whether it's precision ball bearings or robust roller bearings, our catalogue has a solution for you.

3. Consider Load and Speed Ratings

Determine the load capacity and operating speeds required for your application. Follow TIMKEN bearings recommendation for the type and configuration of each bearing to ensure you are selecting the one that will provide you the best performance.

4. Evaluate Environmental Factors

Take into account temperature, humidity, and other environmental factors that may affect bearing performance. Select bearings that are designed to endure the environmental challenges of your application to warrant longevity and reliability based on TIMKEN’s recommendations.

5. Ensure Correct Mounting and Fitment Requirements

Consider the mounting and fitment specifications of your machinery. Ensure that the chosen TIMKEN bearings match these requirements seamlessly for proper installation and optimal performance.

6. Understand Sealing and Lubrication Needs

Assess the level of protection and lubrication requirements for your application. Choose TIMKEN bearings with appropriate sealing options to prevent contamination and ensure long-lasting performance. Select the right lubrication to optimize performance and reduce maintenance needs.

7. Consult with Our Experts

Whenever in doubt, the smart thing to do is consult with an expert. Our team of knowledgeable professionals is here to provide personalized guidance and recommendations tailored to your unique needs. Contact us and we will glad to help you.

Elevate Your Machinery with TIMKEN Bearings

Experience the pinnacle of performance and reliability with the TIMKEN bearings you find at Tuli Shop. Browse our selection, find the perfect bearing for your needs, and elevate your machinery to new heights of excellence.

Trust Tuli Shop for all your bearing needs.

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

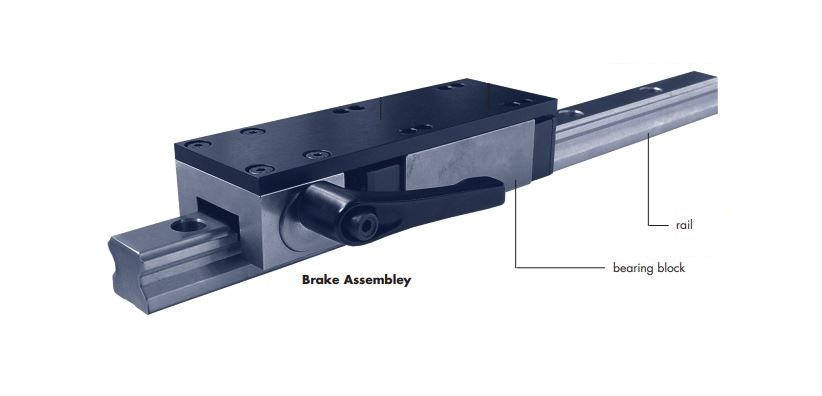

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...