How to remove and replace a bearing

When you realize you have to replace a rolling bearing (either a ball bearing, a roller bearing, a tapered roller bearing, or a thrust bearing), it helps to understand how these precision components function in the larger mechanical system before you get out the cutting wheels and torches and dive into a frustrating job.

Of course, the bearing’s job in the machine is either to support parts which turn relative to another, and/or to transfer forces between moving parts – often one stationary part and one rotating part. For example, the wheel bearings in your car allow the weight of the car to be transmitted to the road through the rolling wheel while minimizing friction and wear. In order to accomplish this task, a rolling bearing is generally comprised of an inner and outer race (rings) separated by balls or cylinders. In the case of rolling bearings, one of the races is attached to the stationary part and one of the races is attached to the rotating part (usually a shaft). Because of the power flowing across the bearing races, the attachment of the races to the mating parts must be strong enough to resist motion at that interface. For this reason, bearings can be a real hassle to remove when they need to be replaced, and an unskilled mechanic can damage the bearing’s housing or shaft with ham-fisted removal techniques.

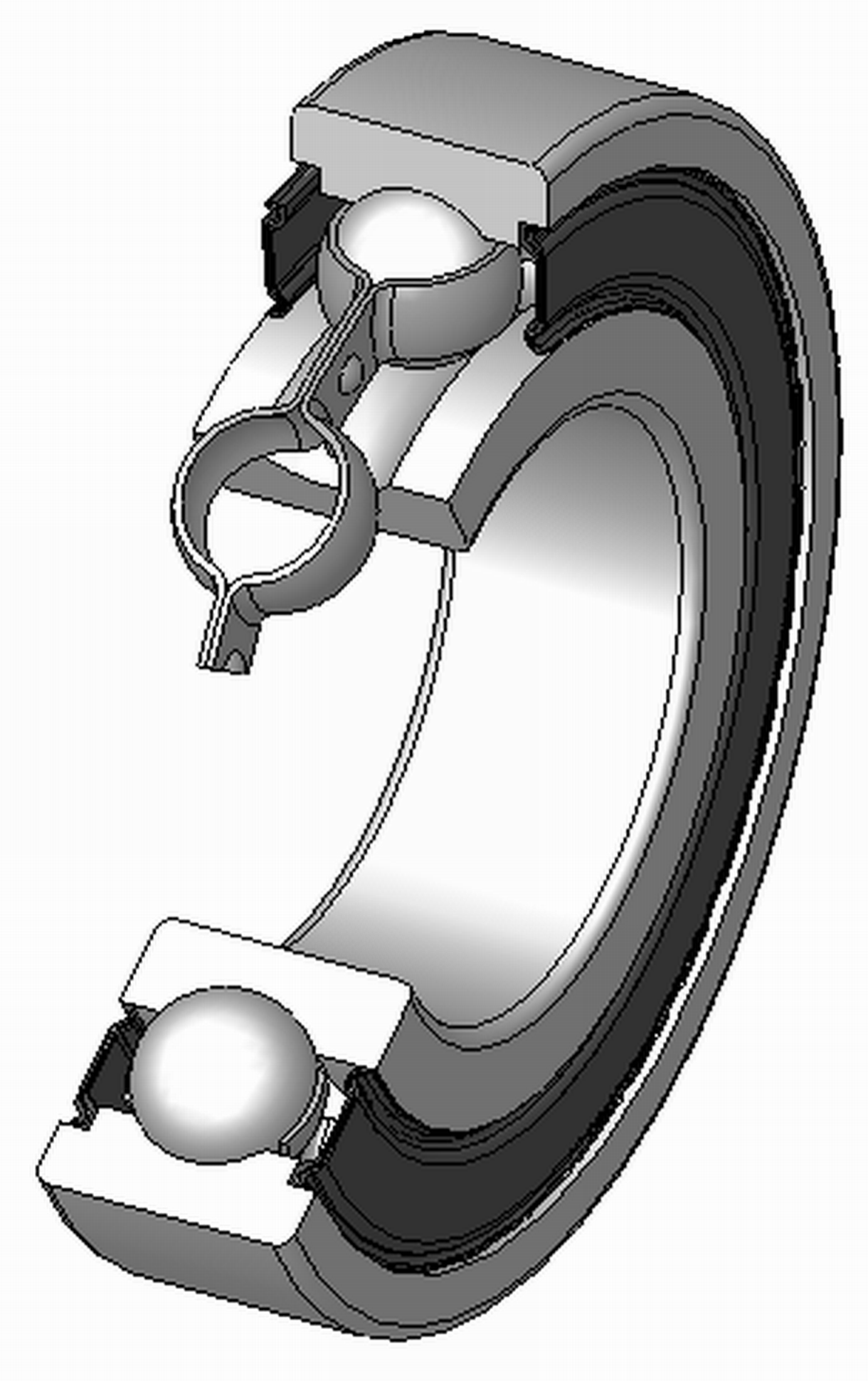

Figure 1: Shown here is a cutaway view of a ball bearing clearly showing the inner race and outer race separated by the ball rollers captured in a cage. This bearing is sealed with the black face rings to help keep contaminants out of the bearing raceway. Image credit: Silberwolf, CC BY 2.5

| Find bearings in e-shop | Online shop |

How Rolling Bearings Are Mounted

There are three attachment categories for the fit between the bearing races and either the housing or the shaft: a clearance fit, an interference fit, and somewhere between those two extremes – a transition fit. In a clearance fit, the two mating parts can be mated without any contact between the mating surfaces. This fit is often used for the static race of the bearing, and since there is usually a large static load on the race when the machine is in operation, that load immobilizes the race. A bearing mounted with a clearance fit is usually very easy to remove.

An interference fit is often used to mount the bearing race on the rotating part. In this fit type, the two mating parts will not fit together without a deformation of at least one of the two mating parts. In the case of a shaft mounted to the inner race of a rolling bearing, the shaft diameter is made to be larger than the inner diameter of the race. Installation in this case requires a press or sometimes changing the temperatures of the mating parts to allow a fit – in our case of the oversized shaft, it is cooled to reduce the diameter and the bearing is heated to increase the inner race’s diameter. At these two temperature extremes, the parts are assembled without interference, but when the assembly returns to ambient temperature the parts are locked together.

A transition fit is the grey area between a clearance fit and an interference fit, and it depends upon the tolerances of the machining process. Parts with a transition fit often have to be assembled with a press or some other means to apply force, but not as much force will be needed as in the clearance fit.

In any case, these fits require a very close machining tolerance, and so are expensive features of the machine. Since replacing the bearing is an operation done to maintain a machine, with the goal of inserting a new bearing after removal of the old one, it is important that these carefully machined surfaces on either the shaft, the housing, or both are not damaged.

Removing a Bearing

Consequently, the tactic one chooses when removing a bearing depends on what type of fit was used to install the bearing in the first place. It’s rare that an interference fit would be used for both the outer and inner race, usually the rotating race is installed with an interference or transition fit, while the static race has a clearance fit. Since the clearance fit will come apart fairly easily, hampered only by corrosion or the buildup of caked bearing grease or other contaminants.

To remove a bearing with an interference fit, purpose-built tools are the best way to ensure that the shaft or bearing housing are not damaged. Especially in cases where the bearing could be rebuilt, removing it without destructive tools is entirely possible. Bearing pulling tools are categorized into two categories – internal and external pulling tools. The external pulling tool removes bearings from shafts where both sides of the bearing are accessible. It has either two or three arms that grip the back of the bearing – usually the outer race – and a screw jack that rests on the end of the shaft. As the screw is advanced against the shaft, the bearing gets pulled along the shaft. These external pullers can also be hydraulically actuated to produce significant forces on the bearing. If a the backside of a bearing on a shaft is inaccessible, then bearing clamps can be used. These wedge-shaped jaws squeeze radially at the rear edge of the bearing to advance it along the shaft and expose the rear surface. Sometimes this is enough to free the bearing, or at least provide enough clearance to insert the arms of a conventional external puller. In any case, these external pullers removes the bearing without damaging the carefully machined surface of the shaft, or bending the shaft.

Figure 2: This is a photograph of a combination internal/external bearing puller. The tool is shown configured as an external puller as the arm-ends wrap inward in the direction of of the screw-jack. Reversing the screw jack relative to the arms allows it to work as an internal puller. (Image is licensed for Tuli’s use from Envato Elements).

An internal pulling tool is used for bearings that are mounted inside of a housing with an interference or transition fit. In this case, the shaft is usually easily removed (because it usually would have a clearance fit) and so the internal puller is inserted through the inner race with inverted arms that catch the back side of the inner race. Using a slide hammer mounted to the arm assembly, as the hammer weight is slid forcefully against the stop, the impact force moves the bearing little by little out of the housing. The repeated actuation of the slide hammer removes the bearing from the housing without damaging the carefully machines surface of the housing.

In either case, after the appropriate pulling tool has been acquired, the first step is to clean the surfaces of the fit as well as possible before beginning to pull. Since the pulling tool only applies force and doesn’t deform the mating parts, any grit or corrosion will not only add to the force required to pull the bearing, but could also permanently damage the mating surfaces that will be used to seat the new bearing.

Reinstalling a Bearing

To reinstall an interference fit bearing, often a press or other specialty tool will be needed to put a uniform force on the bearing to advance the bearing along the shaft or into the housing. If the mechanic just hammers on one side of the bearing, it could damage the bearing. Using a proper fixture is important so that the force imparted by a press or hammer is applied to both races and around the circumference of the bearing evenly. These fixtures avoid transmitting the installation force across the rolling members of the bearing, which is a part of the bearing often not designed to sustain lateral forces.

Just like with installation, surface preparation is crucial when reinstalling a bearing. Any grit, corrosion, or contamination on the surface will cause galling or other damage to these surfaces and impede the performance of the bearing or shorten its service life, so make sure all of the mating surfaces are very clean debris and grease. While you will want to use and apply the proper grease for bearings, you should not lubricate the mating surfaces of the bearing for either clearance or interference fits.

Whether you are removing or replacing ball bearings, roller bearings, or tapered roller bearings, knowing how these critical parts are assembled and disassembled will help maintainers maximize machine health and life.

Leave a Comment

Your email address will not be published. Required fields are marked *