THK Linear Bearings

About the Producer - THK: Precision in Motion

THK Co., Ltd. is a Japanese company known for its expertise in linear motion systems and precision machinery components. The company takes its name from Toughness, High-quality, and Know-how.

Judging from its name, it is clear that they strive for applying their knowledge and experience to develop tough and high-quality products. As they state it, “we aim to contribute to the improvement of society and development of industry by focusing on these three principles in our technology development and product manufacturing processes.”

THK has been revolutionizing industries for decades. With a relentless focus on innovation and quality, THK has earned a reputation for excellence in precision engineering and reliability.

History of THK Linear Bearings

THK was founded in 1971 in Tokyo, Japan under the initial name of Toho Seiko Co., Ltd. Then, in 1972, THK became the first company to develop and commercialize a system that combined rolling contact with linear motion. This system is what we know as the Linear Motion Guides or LM Guides.

The first plant to build the linear motion guides was THK’s Kofu which started operations in 1977. From then on, the company continued to grow exponentially.

In the 1980’s the company expanded production within Japan just years after expanding distribution operations in the US and Germany.

They reach new lands with their manufacturing operations in the 1990s, establishing its presence in the US and Europe.

With this growth came more development. They developed the first Caged Ball LM Guides in 1996 to offer higher performance, and more recently they have provided solutions to applications that include:

- Machine tools

- Industrial robots

- Semiconductor manufacturing systems

- Liquid crystal manufacturing lines

- Railway carriages

- Assistive vehicles

- Medical equipment

- Skyscrapers and residences

- Amusement devices

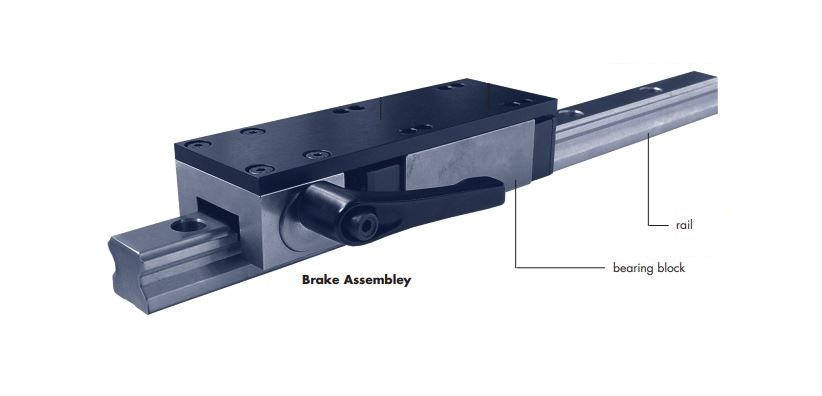

Figure 1 THK linear guide bearings

Where THK Linear Bearings are Made

As you can expect from the expansion described above, THK plats are located in various regions worldwide, with main facilities located in:

- United States of America

- Canada

- Mexico

- Japan

- Germany

- Ireland

- France

- Czech Republic

- China

- Korea

- Thailand

- Vietnam

- Malaysia

- India

THK’s production plants uphold the highest standards of quality and precision, ensuring that every THK linear bearing meets their stringent criteria.

Types of THK Linear Bearings and Linear Motion Products

THK linear bearings come in a diverse range, each designed to meet the unique needs of various industries and applications:

Ball Bushings

Perfect for applications requiring smooth and precise linear motion. THK ball bushings offer low friction and high rigidity, ensuring optimal performance and reliability. Moreover, these bushings offer reduced installation times and costs, and an energy saving operation.

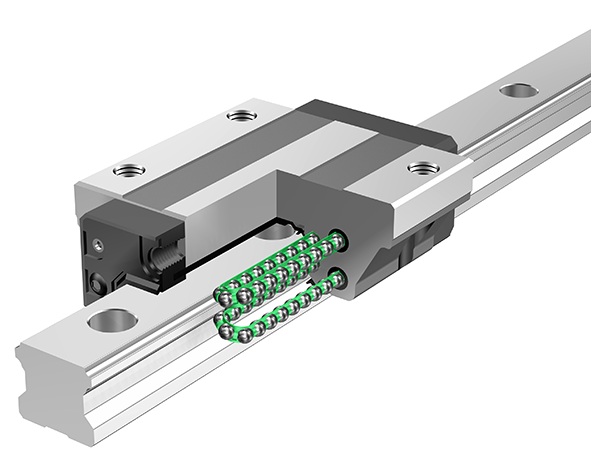

THK Linear Guide Rails

THK linear guide rails are the epitome of precision engineering, designed to facilitate smooth and precise linear motion in various industrial applications. Crafted with meticulous attention to detail and advanced manufacturing techniques, THK linear guide rails offer unparalleled performance and reliability.

THK linear guides are classified into two categories which are “Caged Ball Type” and “Full Ball Type (without ball cage)”.

The cage ball type includes SSR (radial type) and SHS (4-way equal load type) models.

The full cage type includes SR (radial type) and HSR (4-way equal load type) models.

Linear Carriages/Blocks

Designed for heavy-duty applications, THK linear carriages and blocks provide robust support and stability, delivering superior performance in demanding environments.

Figure 2 THK linear bushing

THK Linear Bearings Features - Precision Redefined

Here are the exceptional features that set THK linear bearings apart:

1. Precision Engineering

Each THK linear bearing is designed and manufactured with the know-how of their experts to achieve high precision and guarantee high quality, performance and reliability.

2. High Load Capacity

Built to withstand heavy loads and extreme conditions, THK linear bearings offer exceptional durability and longevity. This results in reduced downtime and reduced maintenance needs.

3. Advanced Material Selection

THK linear bearings are constructed from high-quality materials chosen for their strength, resilience, and ability to withstand harsh operating conditions. This ensures optimal performance and reliability in even the most demanding applications.

4. Smooth and Quiet Operation

Experience smooth and quiet linear motion with THK bearings, enhancing the performance and efficiency of your machinery.

5. Low Friction Design

THK linear bearings are engineered for minimal friction, reducing energy consumption and extending the life of your equipment.

6. Corrosion Resistance

With advanced coatings and materials, THK linear bearings are resistant to corrosion, ensuring reliability even in harsh environments.

7. Wide Range of Sizes and Configurations

From miniature bearings to large-scale solutions, THK offers a comprehensive range of sizes and configurations to accommodate a diverse array of machinery and applications.

Figure 3 THK linear bearing block

How to Select THK Linear Bearings - Your Guide to Making the Right Choice

Choosing the perfect THK linear bearing for your application is crucial. Here's how to make an informed decision:

1. Assess Your Application Needs

Identify the specific requirements and operating conditions of your machinery. This will serve you as a first filter to reduce the universe of linear motion products for your selection.

2. Understand Linear Bearing Types

Familiarize yourself with the different types of THK linear bearings available and their respective advantages. Make sure you get all you need for your linear motion system. Remember we offer more than just the linear bearings.

3. Consider Load and Speed Requirements

Determine the load capacity and operating speeds required for your application. Start comparing with THK’s recommendation until you find the one that matches your needs.

4. Evaluate Environmental Factors

Take into account temperature, humidity, and other environmental factors that may affect bearing performance. Only select the linear bearings and linear motion systems that are designed and manufacture to withstand your specific environmental requirements.

5. Consult with Our Experts

As we always recommend, talk to an expert whenever you are in doubt. Our team of knowledgeable professionals is here to provide personalized guidance and recommendations tailored to your unique needs. Contact us and we will glad to help you.

Elevate Your Machinery with THK Linear Bearings

Experience the precision, reliability, and performance of THK linear bearings from Tuli Shop. Browse our selection, find the perfect bearing for your needs, and take your machinery to new heights of excellence.

Trust Tuli Shop for all your linear bearing needs—where quality meets innovation.

Knowledge Base

-

Read more

Aluminum extrusion brackets are mechanical components that offer great versatility and functionality in various applications. They are essential for c...

-

Read more

Linear rail brakes, also known as clamping brakes or clamping braking elements, play a vital role in achieving safe and precise positioning. Linear ra...

-

Read more

Bearing suppliers play a crucial role in various industries, offering these essential components for machinery. In this industry, we find manufacturer...